If you are currently using nitrogen for tank blanketing, drying, product transfer, purging, flushing, inerting, you should then look at your plant’s compressed air supply as a source to produce your own nitrogen on-site. This is a simple and reliable way that can save you money and give you more control over your gas use.

What are my Generator Product options?

Generally speaking there are two ways to make nitrogen onsite.

- Hollow fiber membrane technology

- PSA (Pressure Swing Adsorption) technology

Quick Estimate Form

The flow rate and purity will determine which technology is best suited for the application. Below is a brief description of both technologies and what applications they are best suited for.

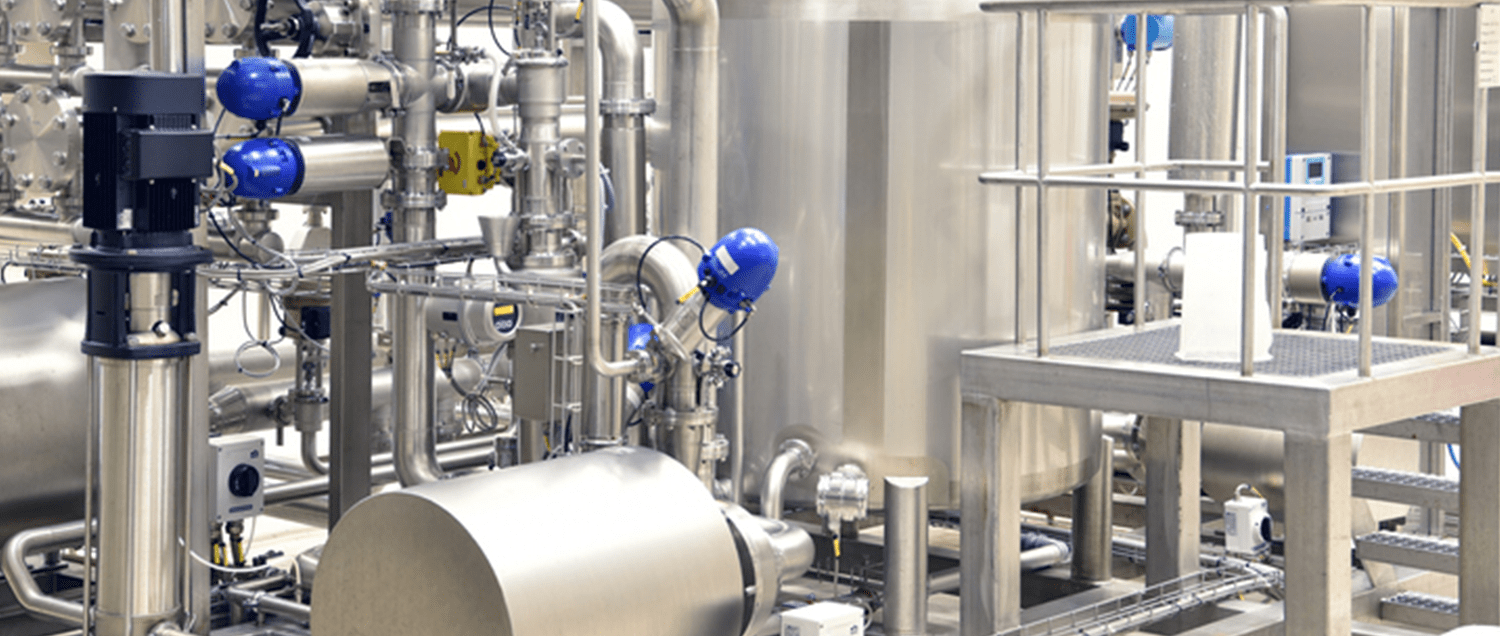

Membrane Technology

Membrane technology works by filtering oxygen from the dry compressed air stream via hundreds of thousands of hollow, polymeric fibers each the diameter of a human hair to produce gaseous nitrogen. The purity of the nitrogen (O2 Content) can be adjusted by regulating the volume of air passed through the membrane. Membrane modules can be added as necessary, so it’s easy to expand as requirements change.

Membrane nitrogen generators are typically used in applications where the purity requirement is below 99.5% (0.5% or higher).

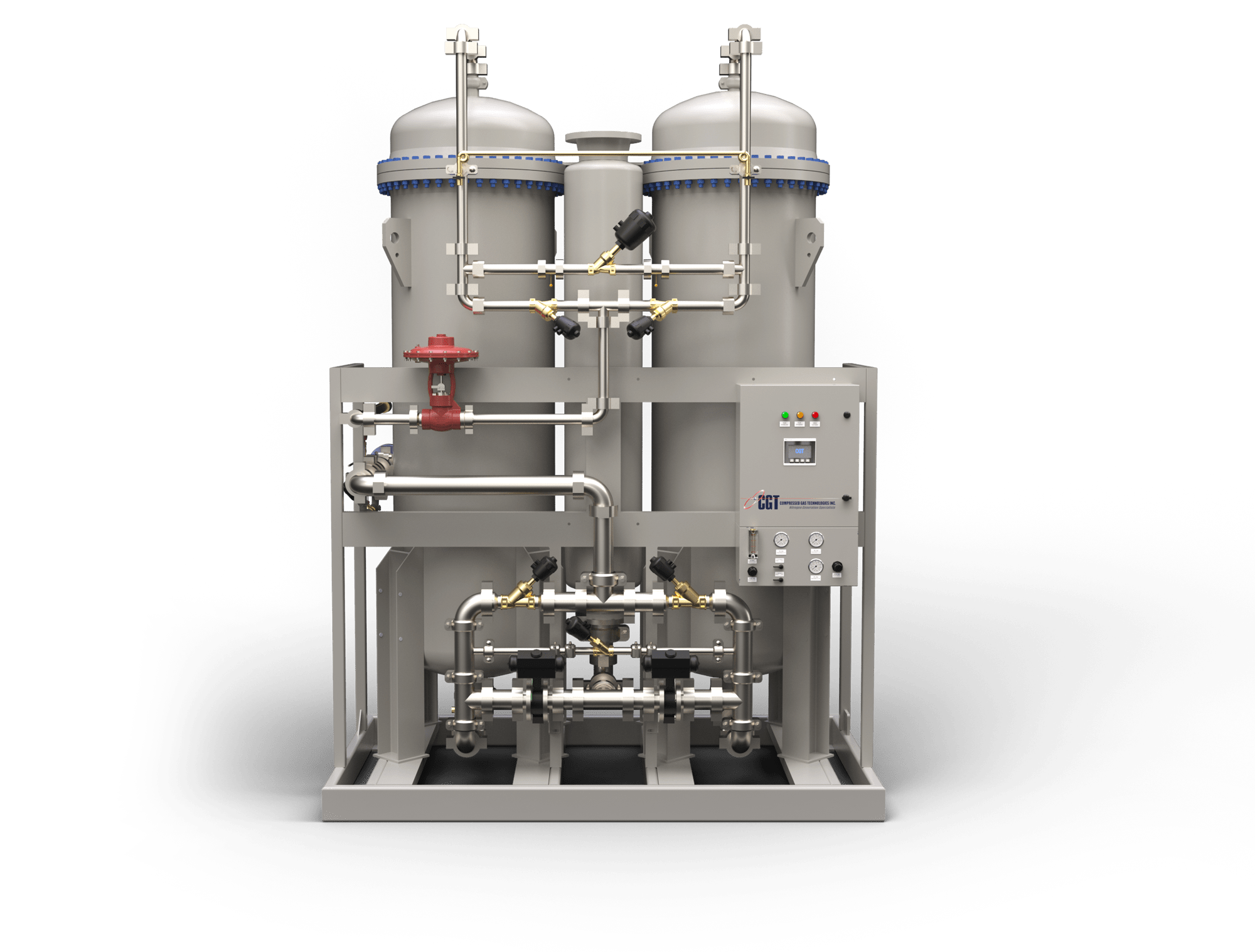

PSA (Pressure Swing Adsorption) Technology

SA technology utilizes two towers which are filled with carbon molecular sieve (CMS). Compressed air enters the bottom of the “online” tower and flows up through the CMS. Oxygen and other trace gases are preferentially adsorbed by the CMS, allowing nitrogen to pass through. After a pre-set time the on-line tower automatically switches to the regenerative mode, venting contaminants from the CMS. Carbon molecular sieve differs from ordinary activated carbons as it has a much narrower range of pore openings. This allows small molecules such as oxygen to penetrate the pores and separate from nitrogen molecules which are too large to enter the CMS. The larger molecules by-pass the CMS and emerge as nitrogen gas.

PSA nitrogen generators are typically used in applications where the purity requirement is higher than 99.5% (0.5% O2 or below).

How Much Does a Nitrogen Generator Cost?

Typically a nitrogen generator will pay for itself in less than two years assuming the nitrogen is being used continuously (70% utilization factor is a rule of thumb) and the process can tolerate some oxygen. The price of industrial gas varies greatly based on geography (proximity to a nitrogen supply source) and volume (how much nitrogen is used) therefore each case will be different.

Maintenance for Generator Products

As with all equipment, service is required on both membrane and PSA nitrogen generators. Membrane nitrogen generators will require semi-annual filter changes as well as. PSA units will also require semi-annual filter changes. They will also require valve rebuilds every two years as well as muffler changes yearly. Both membrane and PSA units will require their oxygen sensors to be replaced every 2-3 years (on units equipped with this feature).