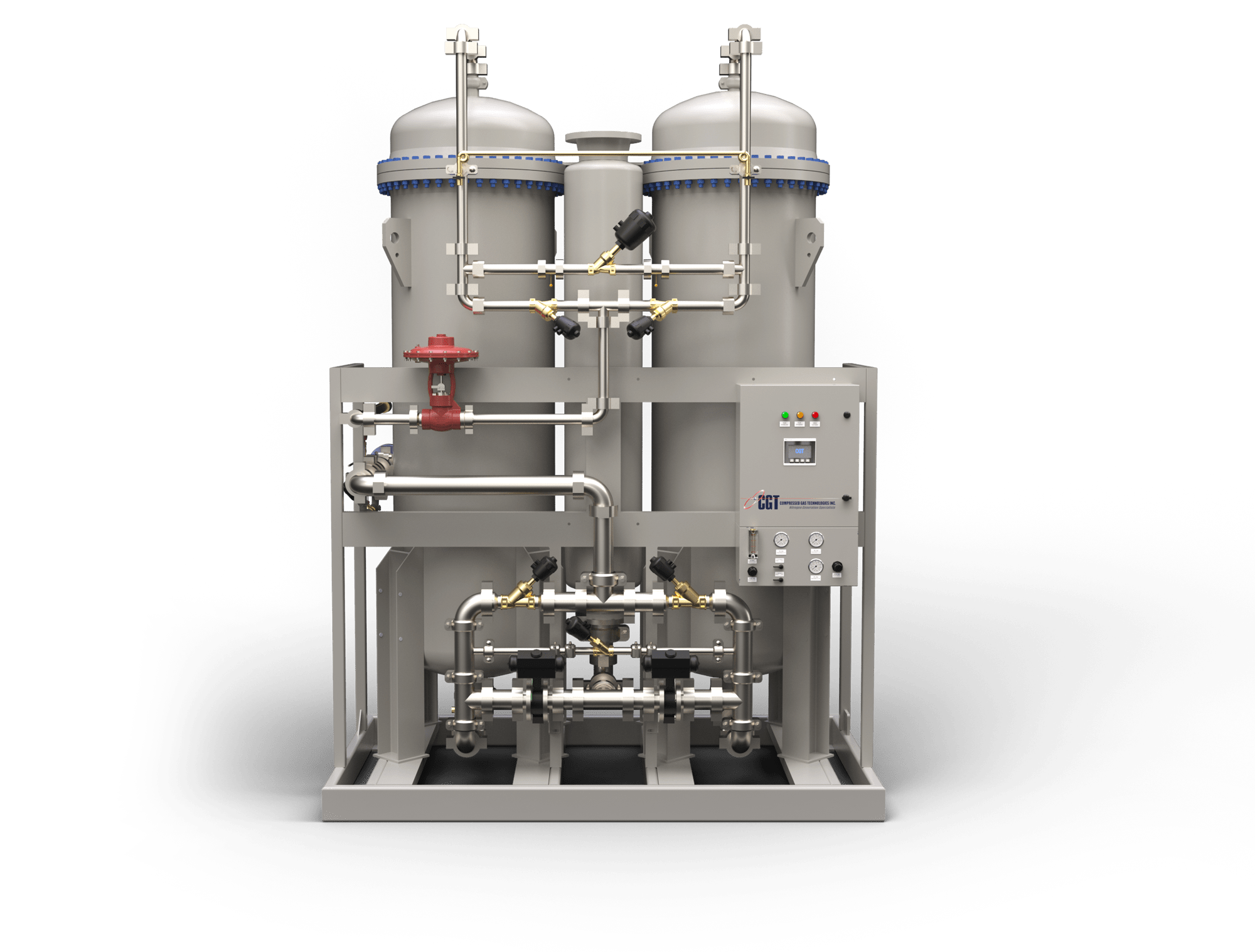

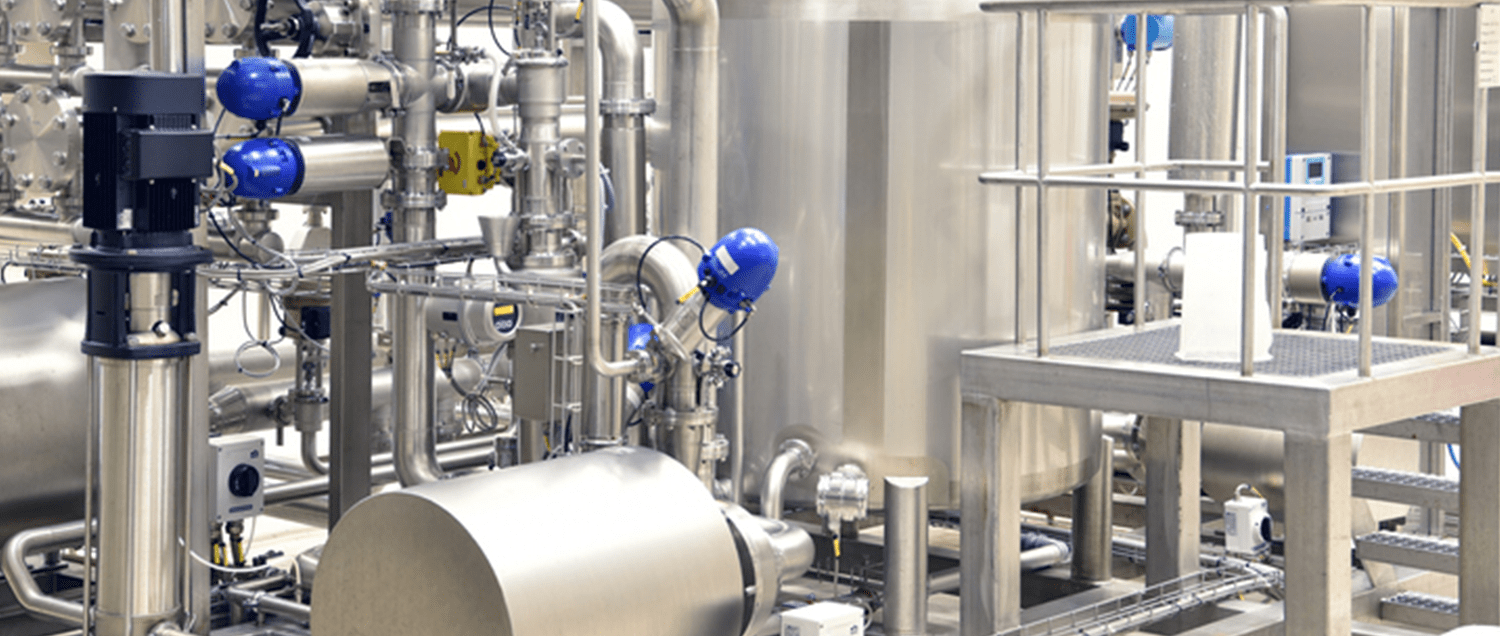

Modular PSA nitrogen generators use patented technology to produce an uninterrupted supply of gaseous nitrogen, on site. This compact system is ideally suited for low-flow, high purity applications that presently employ high-pressure gas cylinders or dewars of nitrogen. With modular PSA nitrogen generators, the inconvenience of gas cylinders and liquid dewars is eliminated. Nitrogen is generated at your location, continuously and reliably, requiring only a supply of compressed air.

HOW MODULAR PSA NITROGEN GENERATORS WORK

PSA nitrogen generators operate on the Pressure Swing Adsorption (PSA) principle to produce a continuous stream of nitrogen gas from compressed air. Pairs of extruded aluminum columns are filled with carbon molecular sieve (CMS). Pretreated compressed air enters the bottom of the on-line column and follows up through the CMS. Oxygen and other trace gasses are preferentially adsorbed by the CMS, allowing nitrogen to pass through. After a pre-set time, the on-line column automatically switches to regenerative mode, venting contaminants from the CMS. Carbon molecular sieve differs from ordinary activated carbons in that it has a much narrower range of pore openings. This allows small molecules such as oxygen to penetrate the pores and be separated from nitrogen molecules which are too large to enter the CMS. The larger molecules of nitrogen by-pass the CMS and emerge as the product gas.

FEATURES & BENEFITS

Modular/ Expandable: Systems are easily upgraded by simply adding additional “columns” or “banks”. Our units grow as your business grows!

Multistage Filtration: Each nitrogen generator incorporates the most advanced filtration systems available on the market today. Protecting the unit from compressed air contamination, ensuring years of trouble-free operation.

Energy Efficient: CGT PSA nitrogen generators are the most efficient systems available on the market today with the lowest air/ nitrogen ratios. Control systems are available to optimize efficiency for variable flow applications.

Connectivity: Ready for Industry 4.0. Monitor your nitrogen generator from almost any device and get real time information that is pertinent to your facility.

PERFORMANCE DATA & SPECS

| Model | Nitrogen Purity | Approximate Dimensions & Weights (lbs) | ||||||||||||||

| 95% 5% | 96% 4% | 97% 3% | 98% 2% | 99% 1% | 99.5% .50% | 99.9% .10% | 99.95% 500ppm |

99.975% 250ppm | 99.99% 100ppm |

99.995% 50ppm |

99.999% |

|||||

| Flow Rate at the Outlet (scfh)* | Height | Width | Depth | Weight | ||||||||||||

| GEN2-1110 | 364 | 335 | 293 | 258 | 205 | 48″ | 16″ | 23″ | 176 | 71 | 60 | 32 | 48″ | 16″ | 23″ | 176 |

| GEN2-2110 | 727 | 671 | 586 | 516 | 410 | 48″ | 16″ | 30″ | 242 | 141 | 120 | 64 | 48″ | 16″ | 30″ | 242 |

| GEN2-3110 | 1091 | 1006 | 879 | 773 | 614 | 48″ | 16″ | 36″ | 374 | 212 | 180 | 95 | 48″ | 16″ | 36″ | 374 |

| GEN2-2130 | 1324 | 1218 | 1070 | 932 | 742 | 71″ | 16″ | 30″ | 365 | 297 | 254 | 180 | 71″ | 16″ | 30″ | 365 |

| GEN2-3130 | 1986 | 1828 | 1605 | 1398 | 1112 | 71″ | 16″ | 36″ | 490 | 445 | 381 | 270 | 71″ | 16″ | 36″ | 490 |

| GEN2-4130 | 2649 | 2437 | 2140 | 1865 | 1483 | 71″ | 16″ | 43″ | 610 | 593 | 509 | 360 | 71″ | 16″ | 43″ | 610 |

| GEN2-6130 | 3973 | 3655 | 3210 | 2797 | 2225 | 71″ | 16″ | 56″ | 852 | 890 | 763 | 540 | 71″ | 16″ | 56″ | 852 |

| GEN2-8130 | 5297 | 4873 | 4280 | 3729 | 2966 | 71″ | 16″ | 69″ | 1100 | 1187 | 1017 | 720 | 71″ | 16″ | 69″ | 1100 |

| GEN2-10130 | 6092 | 5604 | 4922 | 4289 | 3411 | 71″ | 16″ | 83″ | 1350 | 1365 | 1170 | 828 | 71″ | 16″ | 83″ | 1350 |

| GEN2-12130 | 7072 | 6506 | 5714 | 4979 | 3960 | 71″ | 16″ | 96″ | 1600 | 1584 | 1385 | 962 | 71″ | 16″ | 96″ | 1600 |

*At 110 psig inlet pressure and 70˚F ambient temperature. For outlet flow at all other conditions, please contact us. Air factors listed may vary by 5%.