Aluminum Degassing

Aluminum Degassing

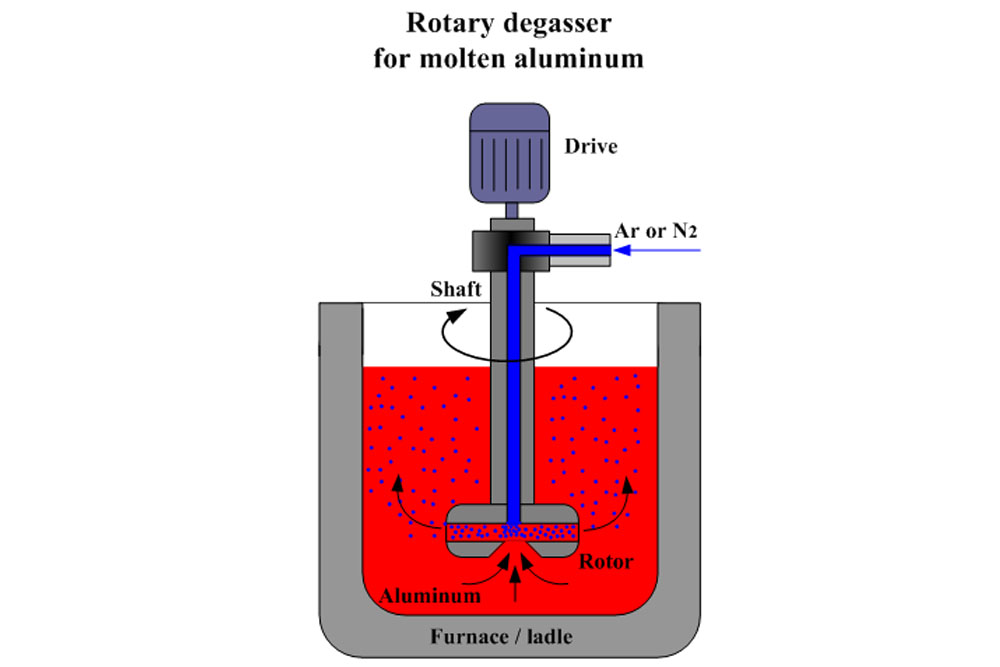

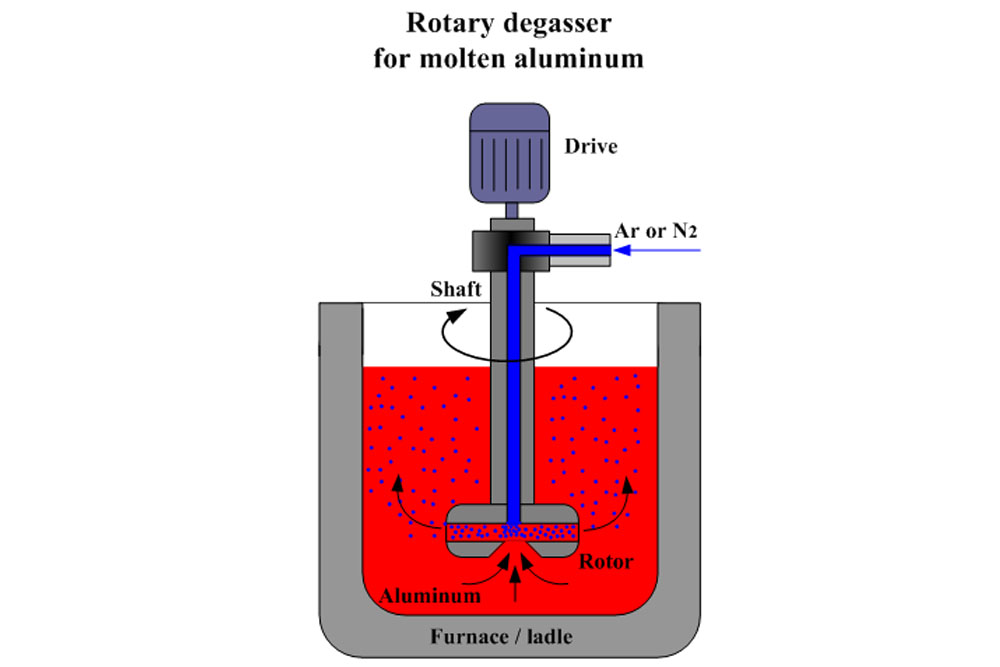

Hydrogen is removed from liquid aluminum by bubbling through nitrogen gas. The hydrogen is drawn to the to the bubbles and carried up through the aluminum to release on the surface.

This compact system of nitrogen generation is ideally suited for high flow applications that presently employ liquid nitrogen bulk delivery systems.

This compact system is ideally suited for low-flow applications that presently employ high-pressure gas cylinders or dewars of nitrogen.

HSS Membrane Series nitrogen generators use patented membrane technology to produce an uninterrupted supply of gaseous nitrogen, on site.

NitroPure is designed specifically for laser cutting, offering the highest purity, pressure, and efficiency.

CGT nitrogen generators are installed in private labs; universities; pharmaceutical companies providing high quality lab gas nitrogen for many years. These plug and play systems eliminate the need to handle high pressure cylinders or liquid nitrogen dewars, providing rapid ROI’s.

Nitrogen Generators are extremely reliable and very cost effective solutions for industrial applications such as electronics, rapid prototyping, military, aerospace, heat treat, and aluminum extrusion.

Nitrogen Generators are used for MAP (modified atmospheric packaging), CAS (controlled atmospheric storage), sparging, blanketing, and bottling. Customers range from snack foods, coffee, wineries, breweries, oil refineries, and oil packaging.

Nitrogen is a dry, inert gas used in a wide range of applications where oxygen may be harmful to the product or process, such as laser cutting.

CGT nitrogen generators have been supplying nitrogen to the oil & gas industry since 2001 for uses such as laboratories, gas seals, off-shore, instrumentation, blanketing and purging.

Hydrogen is removed from liquid aluminum by bubbling through nitrogen gas. The hydrogen is drawn to the to the bubbles and carried up through the aluminum to release on the surface.