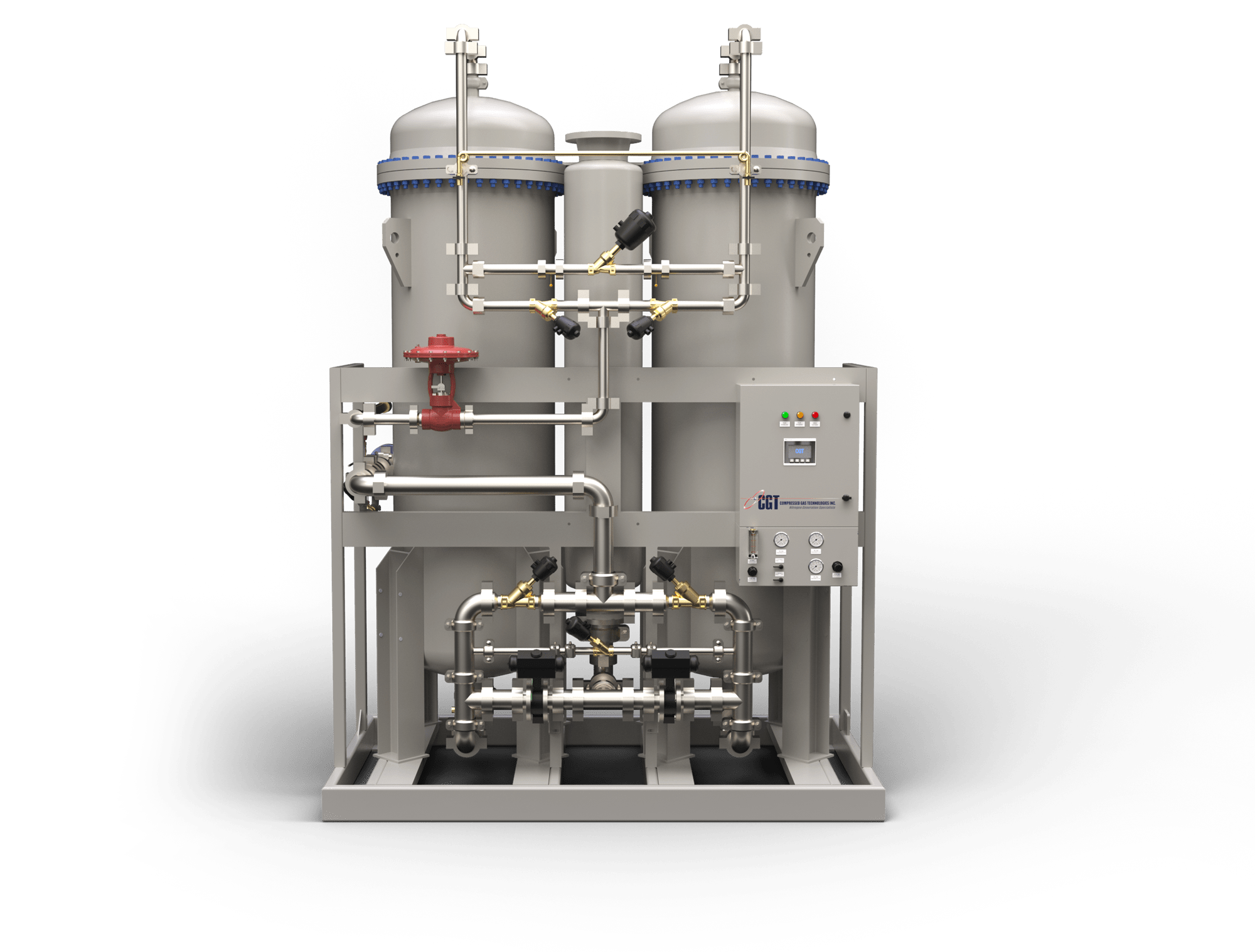

Modular PSA Nitrogen Generator

Say goodbye to gas cylinders and hello to efficiency. Imagine a world where your nitrogen supply is limitless, on-demand, and tailored to your needs. With our Modular PSA Nitrogen Generators, that world is your reality.

Specifications

| Model | Nitrogen Purity | Approximate Dimensions & Weights (lbs) | ||||||||||||||

| 95% 5% | 96% 4% | 97% 3% | 98% 2% | 99% 1% | 99.5% .50% | 99.9% .10% | 99.95% 500ppm |

99.975% 250ppm | 99.99% 100ppm |

99.995% 50ppm |

99.999% |

|||||

| Flow Rate at the Outlet (scfh)* | Height | Width | Depth | Weight | ||||||||||||

| GEN2-1110 | 364 | 335 | 293 | 258 | 205 | 48″ | 16″ | 23″ | 176 | 71 | 60 | 32 | 48″ | 16″ | 23″ | 176 |

| GEN2-2110 | 727 | 671 | 586 | 516 | 410 | 48″ | 16″ | 30″ | 242 | 141 | 120 | 64 | 48″ | 16″ | 30″ | 242 |

| GEN2-3110 | 1091 | 1006 | 879 | 773 | 614 | 48″ | 16″ | 36″ | 374 | 212 | 180 | 95 | 48″ | 16″ | 36″ | 374 |

| GEN2-2130 | 1324 | 1218 | 1070 | 932 | 742 | 71″ | 16″ | 30″ | 365 | 297 | 254 | 180 | 71″ | 16″ | 30″ | 365 |

| GEN2-3130 | 1986 | 1828 | 1605 | 1398 | 1112 | 71″ | 16″ | 36″ | 490 | 445 | 381 | 270 | 71″ | 16″ | 36″ | 490 |

| GEN2-4130 | 2649 | 2437 | 2140 | 1865 | 1483 | 71″ | 16″ | 43″ | 610 | 593 | 509 | 360 | 71″ | 16″ | 43″ | 610 |

| GEN2-6130 | 3973 | 3655 | 3210 | 2797 | 2225 | 71″ | 16″ | 56″ | 852 | 890 | 763 | 540 | 71″ | 16″ | 56″ | 852 |

| GEN2-8130 | 5297 | 4873 | 4280 | 3729 | 2966 | 71″ | 16″ | 69″ | 1100 | 1187 | 1017 | 720 | 71″ | 16″ | 69″ | 1100 |

| GEN2-10130 | 6092 | 5604 | 4922 | 4289 | 3411 | 71″ | 16″ | 83″ | 1350 | 1365 | 1170 | 828 | 71″ | 16″ | 83″ | 1350 |

| GEN2-12130 | 7072 | 6506 | 5714 | 4979 | 3960 | 71″ | 16″ | 96″ | 1600 | 1584 | 1385 | 962 | 71″ | 16″ | 96″ | 1600 |

*At 110 psig inlet pressure and 70˚F ambient temperature. For outlet flow at all other conditions, please contact us. Air factors listed may vary by 5%.

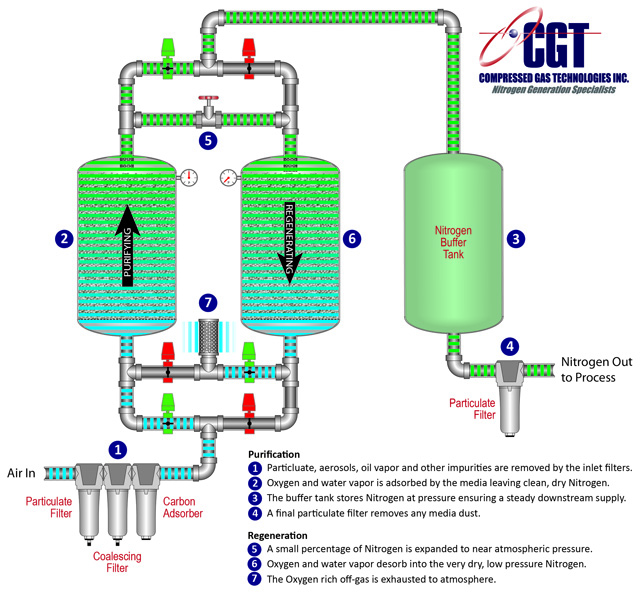

How PSA Nitrogen Generators Work

Ready to Transform Your Nitrogen Supply?

Eliminate the hassles of gas cylinders and liquid dewars. Embrace a

continuous, reliable, and efficient nitrogen supply tailored to your needs.