CGT nitrogen generation systems are installed in food packaging companies ranging from single pouch packaging all the way up to large vegetable oil refineries. These units eliminate the need to handle high pressure cylinders or liquid dewars as well as bulk delivery, providing rapid ROI’s.

INSTALLATIONS

One of North America’s largest fast food pizza companies was opening a new manufacturing facility on the east coast and needed to blanket a vegetable oil tank with nitrogen. After looking at all their options they chose one of our membrane nitrogen generators because of the simple plug-and-play design. The unit was up and running within a few minutes and has been operating trouble-free for years.

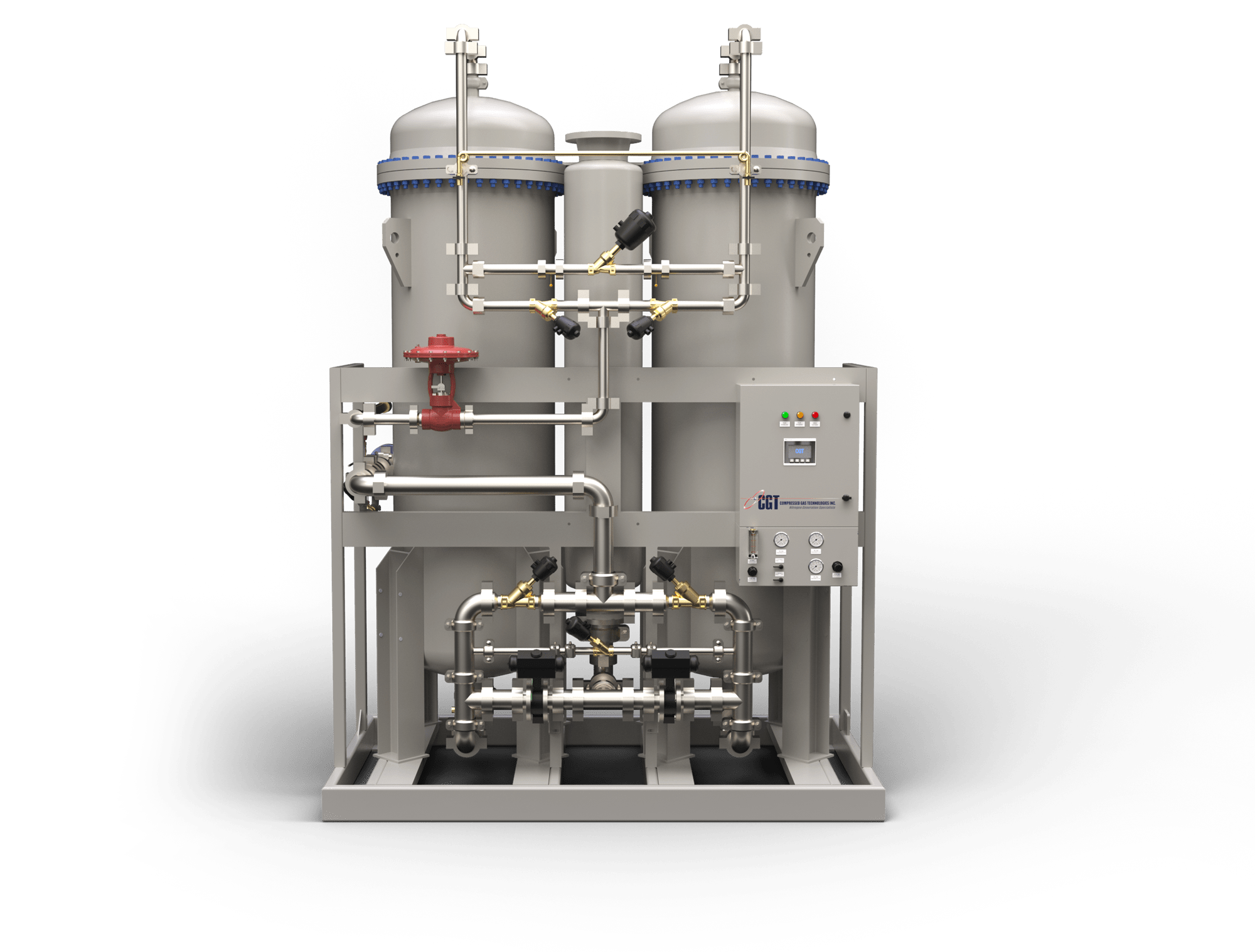

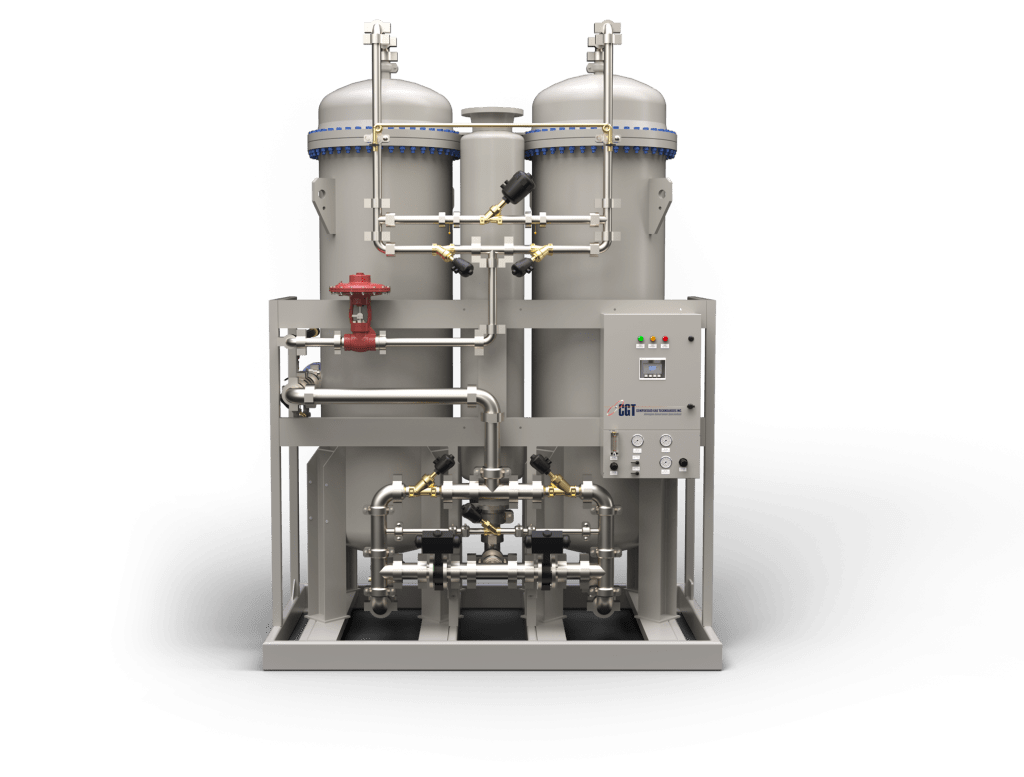

A west coast manufacturer of specialty noodles was looking at alternatives to their liquid nitrogen dewars because of the safety issues of handling these tanks. CGT recommended a modular PSA nitrogen generator which allowed the company to eliminate the dewars, but also was compact, saving valuable floor space.

A Midwest popcorn manufacturer, that has grown to become one of the largest in the United States, added new packaging equipment and needed to double their nitrogen capacity. They simply added the extra capacity requirement from the modular nitrogen generator CGT had supplied years ago. The upgrade was simple, efficient, and cost effective.

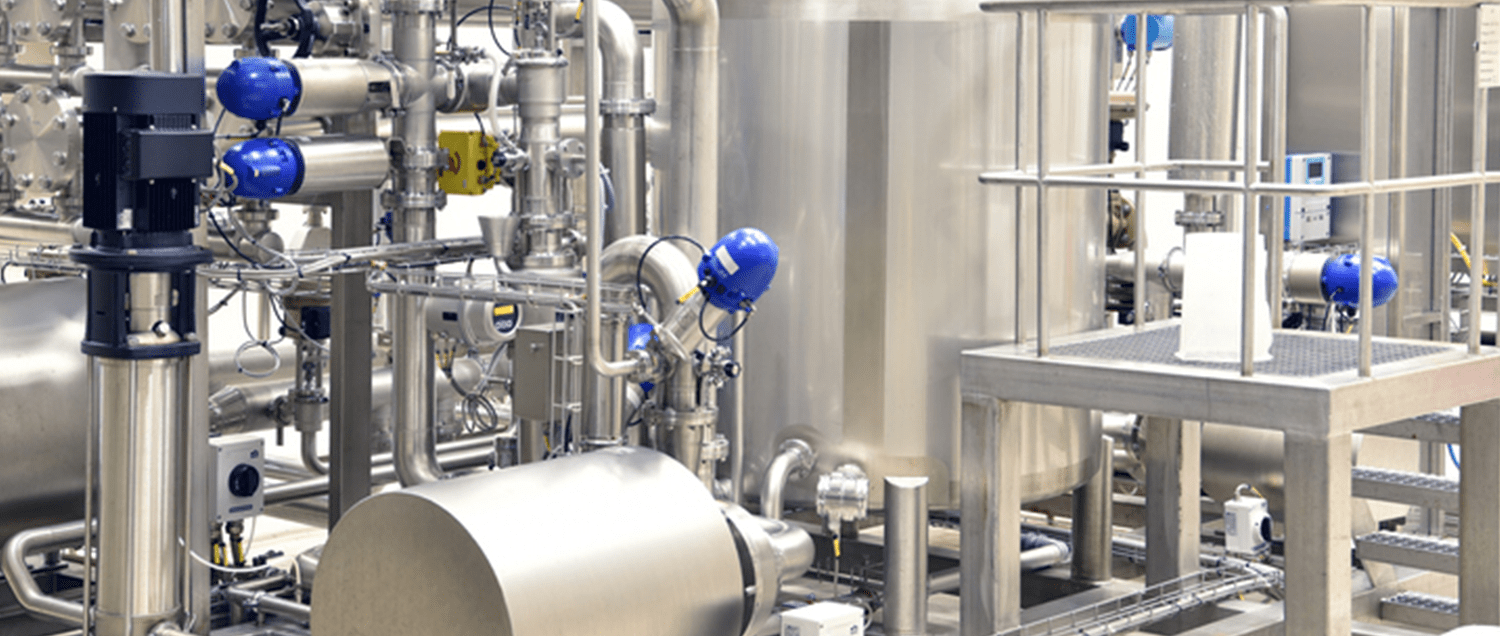

Vegetable oil refineries consume large quantities of nitrogen. CGT worked closely with one of the worlds largest food suppliers and designed a nitrogen system to reduce their nitrogen consumption. A 350 hp air compressor and PSA nitrogen generator was supplied; installed; commissioned on time and under budget providing substantial savings year after year.