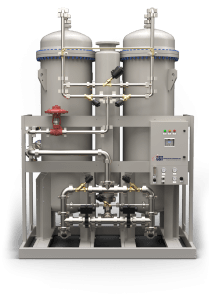

CGT nitrogen generation systems are installed in numerous applications ranging from chemical blanketing; electronics; heat treatment; rapid prototyping; power generation; plastics and many, many more. These units eliminate the need to handle high pressure cylinders or liquid dewars as well as bulk delivery, providing rapid ROI’s.

INSTALLATIONS

One of North America’s largest manufacturers of asphalt shingles wanted to replace their nitrogen cylinder usage. After doing extensive research they chose one of our membrane nitrogen generators because of the simple plug and play design. The unit was up and running within a few minutes and has been operating trouble-free for years.

A worldwide manufacturer of mobility and consumer goods was looking at alternatives to their liquid nitrogen dewars for their 3D Printers. The company’s health and safety department had deemed the liquid supply as unsafe and started to research alternatives. After discussing their options with our nitrogen specialists, the company purchased an installed a system that was quiet and user friendly.

One of the world’s largest electronics manufacturers Mexico facility, installed a modular PSA nitrogen generator from CGT in 2005. Throughout the years the company has added new manufacturing lines and was easily able to increase the capacity of their nitrogen system by simply adding additional “banks”. The modular design has given them the flexibility to meet their companies growing demand.

An ethanol producer was building a new facility in the Midwest and needed a large supply of nitrogen. After thoroughly reviewing their nitrogen supply options the company chose a high flow PSA nitrogen generator over a bulk liquid nitrogen supply. An engineering review of numerous nitrogen generator suppliers was done, and CGT was the preferred supplier based on their experience and low cost of ownership (capital and operating expenses combined).