From Halloween through New Year’s Eve, family get-togethers, office parties and huge piles of leftovers pack 1 to 2 pounds on the average American. Faced with the perennial New Year’s resolution to lose the extra girth, dieters re-fit their lunch bags and dinner plans, replacing high calorie foods with salads and vegetables. But the holiday hangover of returning to a 40+ hour work week and playing catch up at home can make it difficult to stay on track. The ease of processed food takes precedent over even the best laid plans for improved health.

The convenience of bagged salads provide a popular tool in the fight between eating healthier and maintaining a busy lifestyle. Unfortunately, pre-cut lettuce and vegetables wilt faster than New Year’s resolve when left exposed to oxygen. As soon as lettuce is cut enzymatic oxidation kicks in, eventually resulting in the brown, unappetizing stuff found lurking in the bottom of many a refrigerator crisper drawer.

The good news: In conjunction with other factors, such as CO2 concentration and temperature control, decay is slowed greatly when oxygen is reduced in the bag. This means that lettuce and other vegetables can be cut into ready to use portions but still maintain an acceptable shelf life.

Changing any aspect inside a food package is called Modified Atmosphere Packaging (MAP). Reducing oxygen in a bag of ready to use salad, for example, is accomplished by “flushing” the bag and / or product with nitrogen. Dry nitrogen gas displaces much of the ambient atmosphere (which contains about 21% oxygen), slowing the rate of decay without the use of additional preservatives.

One common method to obtain the nitrogen gas used in the MAP process is by purchasing it from the gas company. Deliveries of N2 are made in either gas form (high pressure cylinders) or in liquid form (large liquid dewars or stationary, refillable bulk tanks). Depending on the method, the nitrogen user is responsible for changing tanks when they empty, monitoring usage, maintaining a contract, paying bills, and so on.

In an industry built on convenience, many salad packagers have found a less hands on way to source a clean, reliable source of nitrogen. Since most of the remaining atmosphere that’s not oxygen is nitrogen – about 78% – there is an endless supply of the gas needed for the MAP process available at every food packaging plant. The only trick is, how do you grab it out the air?

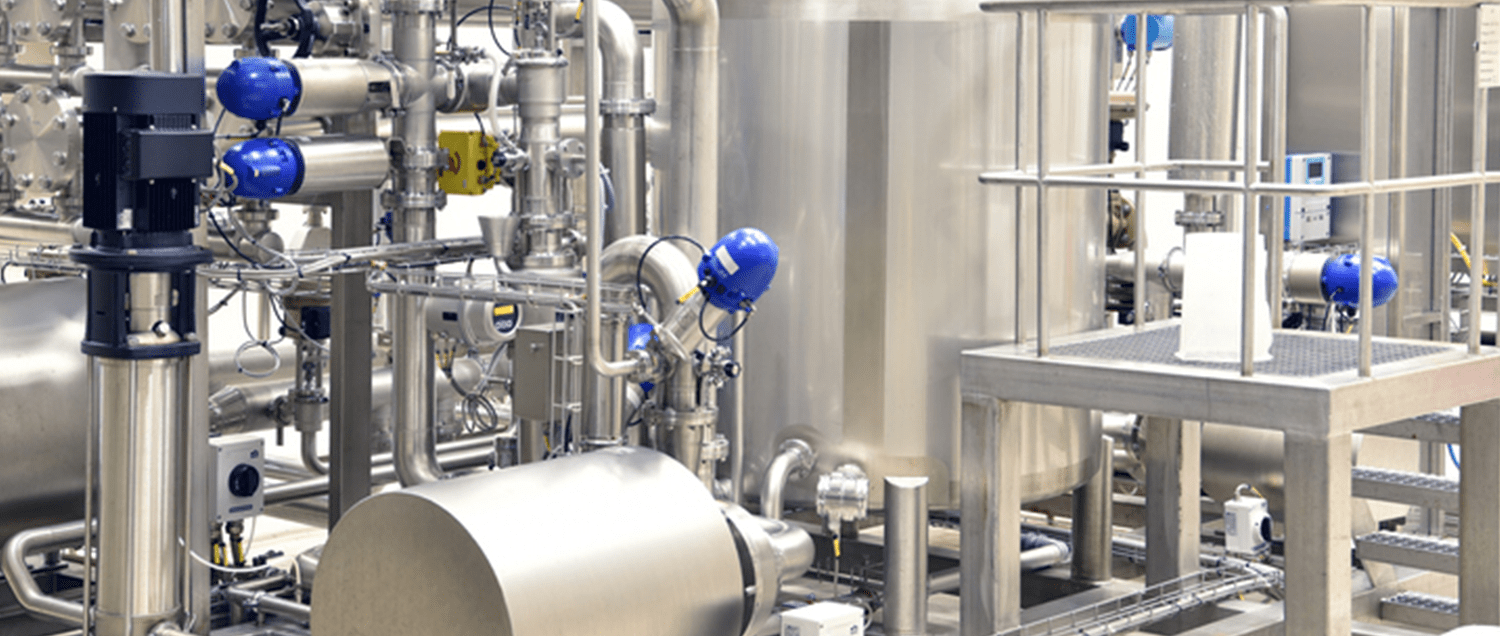

The first step is to compress atmospheric air. Most food packagers already do this for other uses. A portion of the compressed air is then supplied to a nitrogen generator which acts as an oxygen filter. Either using a membrane or a carbon molecular sieve, the nitrogen generator allows nitrogen to pass through while trapping most of the oxygen.

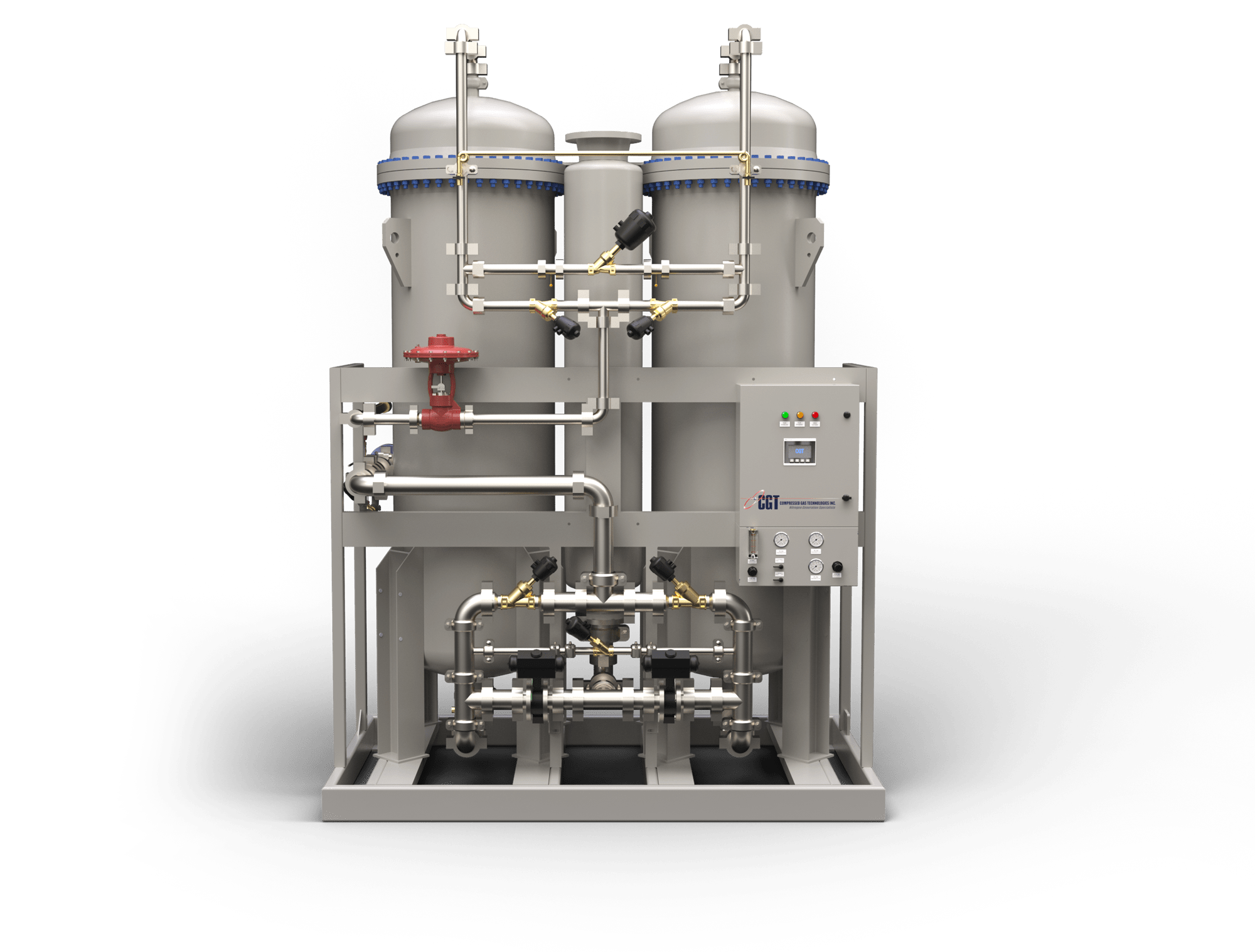

A well-built nitrogen generator is a plug and play system. Once installed, most only require a few minutes of maintenance every 6 or 12 months. This means there is no need to maintain a contract, monitor supply, or change a tank – ever again.

To learn how a nitrogen generator can make MAP as easy as, well, making a salad, contact the nitrogen experts at Compressed Gas Technologies. Thirteen years of experience in the food packaging industry and extensive knowledge of both membrane and PSA nitrogen generators places them in just the right position to help analyze your nitrogen use and the specific benefits of making your own N2.