NitroPure – Laser Cutting

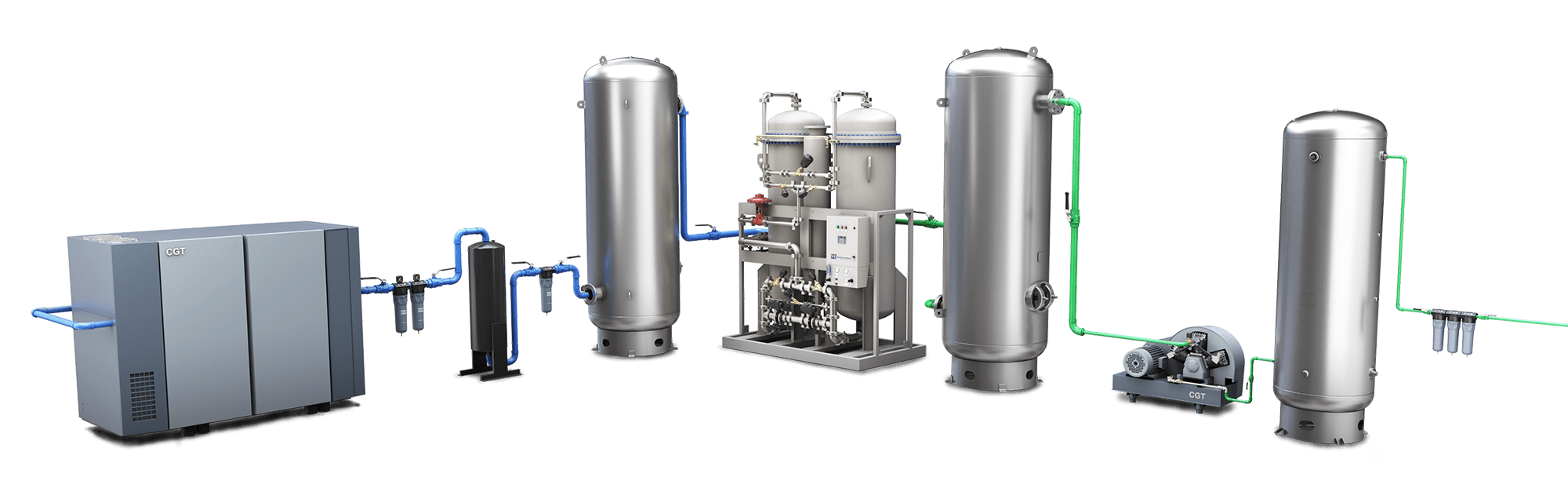

HOW IT WORKS

NitroPure is designed specifically for laser cutting, offering the highest purity, pressure, and efficiency. Ambient air is compressed using a premium air compressor. Dry compressed air then enters a high efficency filtration package. The clean, dry, oil-free air feeds a PSA nitrogen generator which separates the oxygen from the compressed air stream, leaving high purity nitrogen. From here, the nitrogen is boosted to the pressure required by the laser by the nitrogen booster compressor. A final filtration package ensures only high quality nitrogen is supplied to the laser.

FEATURES & BENEFITS

ROI: Generate your own nitrogen in house. Typical payback is 18-36 months.

Reliability: A true industrial nitrogen generator designed for 24 x 7 operation. High quality, long life components keep maintenance to a minimum and ensure trouble-free operation for many years.

Multistage Filtration: Each nitrogen generator incorporates the most advanced filtration systems available on the market today. Protecting the membrane from compressed air contamination, ensuring years of trouble-free operation.

Lowest cost of ownership: Designed for 24 x 7 operation. Minimal maintenance is required keeping yearly operating costs low.

TECHNICAL DATA - ASSIST GAS (CO2 & FIBRE LASERS)

| Model | Flow Rate | Purity | Pressure** |

| NitroPure AG 2000 | 2000 – 4000 scfh | 95% – 99.99% | 200 – 500 psig |

| NitroPure AG 4000 | 4000 – 6000 scfh | 95% – 99.99% | 200 – 500 psig |

| NitroPure AG 6000 | 6000 – 8000 scfh | 95% – 99.99% | 200 – 500 psig |

| NitroPure AG 8000 | 8000 – 10,000 scfh | 95% – 99.99% | 200 – 500 psig |

TECHNICAL DATA - BEAM PURGE

| Model | Flow Rate | Purity | Pressure** |

| NitroPure BP Series | 120 – 1300 scfh | up to 99.99% | 75 – 200 psig |

Call now to size a system and get pricing immediately!!

1-877-737-7760

Complete this form to request additional information about Laser Cutting.