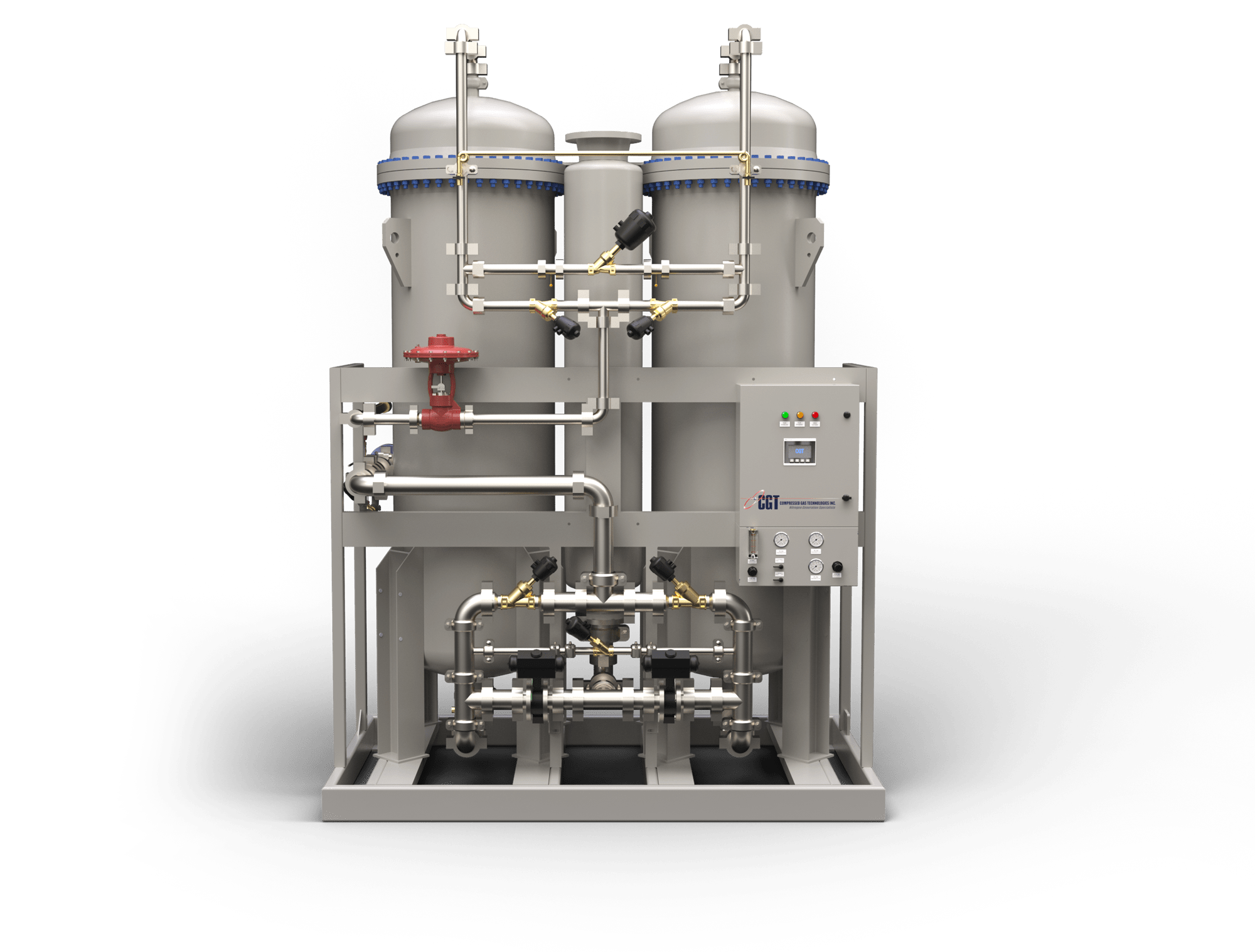

CGT nitrogen generators have been supplying nitrogen to the laser industry for beam purge and assist gas, since 2001. Our systems are extremely reliable and very cost effective. The following is a list of some of the laser equipment connected to our nitrogen generators: AMADA, Bystronic; Cincinnati; Mitsubishi; Trumpf.

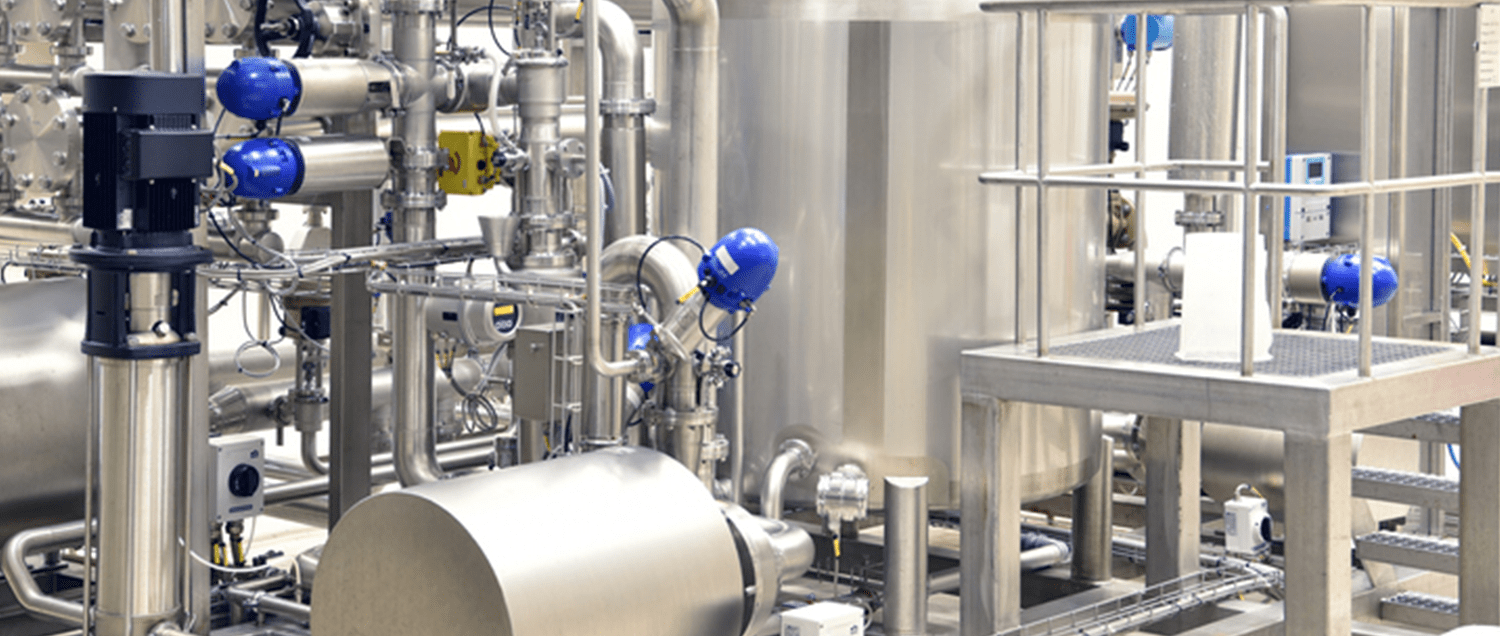

Laser cutting with nitrogen is intended for applications where oxidation is not wanted. For example, an oxide layer can cause paint to adhere less strongly on non-alloy steel. If non-alloy steel is painted after cutting, the cutting gas should be nitrogen. Weldable steel components laser cut with oxygen will not pass the bending test. Stainless steel loses its corrosion resistance when cut with oxygen, and aluminum pieces cut with oxygen have an uneven and burred cut surface.

When nitrogen is used as the cutting gas, the laser beam melts the material, and the nitrogen blows away the molten material from the cutting groove. Since no exothermic reaction takes place, the cutting speed is much slower than when cutting with oxygen. To ensure a burr-free cut edge, the laser beam must usually be focused on the bottom surface of the plate.

Examples

[su_box title=”Precision Metal Fabricator, Midwest” style=”default” box_color=”#16184b”]CGT supplied its first NitroPure system in 2004 to a Minnesota metal fabricator. The system, which supplies high purity nitrogen, allows the company to cut 16 gauge metal on their 2000 & 4000 watt Amada lasers at the same time. According to the owner, the nitrogen generator has paid for itself many times over. [/su_box]

[su_box title=”Fireplace Manufacturer, West Coast” style=”default” box_color=”#16184b”]A CGT NitroPure system was installed in 2011 to supply high purity nitrogen for a Bystronic 4kw fiber laser. The new laser was more efficient than their previous CO2 laser; however they were running into supply issues due to the higher nitrogen consumption. Since installing the NitroPure system the company has never run out of nitrogen allowing them to cut around the clock, when needed. [/su_box]

[su_box title=”Full Service Contract Manufacturer, West Coast” style=”default” box_color=”#16184b”]After finalizing the purchase of his new Trumpf TruLaser 3040, the owner of a Colorado fab shop knew the next step was to find a nitrogen generator. The Trumpf service technician made it easy, recommending a NitroPure unit from CGT after seeing a unit in the field. Within a very short period of time the owner installed a high purity, high pressure NitroPure system. The unit has been running flawlessly since it was started in early 2017.[/su_box]

[su_box title=”Manufacturer of Specialty Architectural Products, East Coast” style=”default” box_color=”#16184b”]A leading designer and manufacturer of specialty architectural products, used around the world, were looking to replace their bulk liquid nitrogen. CGT suggested a NitroPure system to supply high purity, high pressure nitrogen to the companies Trumpf & Prima lasers. In early 2018 the company moved forward with the project and installed the nitrogen system. It has been operating 24 hours a day, 5 days a week with excellent cut quality.[/su_box]

Nitrogen Generators for Laser Cutting Applications:

Download our NitroPure Brochure for more information about Nitrogen Generation for Laser Cutting.