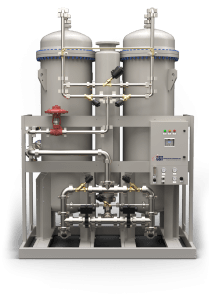

CGT nitrogen generators have been supplying nitrogen to the oil & gas industry since 2001 for uses such as laboratories, gas seals, off-shore, instrumentation, blanketing and purging.

INSTALLATIONS

A new natural gas plant was being constructed in Alaska and the company required a supply of nitrogen for their facility. A local engineering company was tasked to find a reliable nitrogen supply for the remote facility. After an in-depth review of their supply options they chose a CGT membrane nitrogen generation system because of its simple, reliable, plug and play design. CGT supplied the feed air system, filtration package, nitrogen generators.

A Houston oil and gas company were using nitrogen cylinders to purge instrumentation panels at numerous locations throughout the facility. Handling of the cylinders became a health and safety concern, so the company investigated alternatives. CGT recommended modular buildings that could house the air compressor; air dryer; and nitrogen generator. An unlimited supply of nitrogen was now available eliminating handling of the high-pressure nitrogen cylinders.

A natural gas extraction plant located in Alberta Canada continues to grow. As the plant expands, so does their nitrogen demand. By simply adding additional “banks” to their modular nitrogen generator, the facility can easily match the new demand. CGT works closely with the engineering team making recommendations for the auxiliary items that are also required (compressed air; filtration; nitrogen storage tanks).

A large oil refinery located in Columbia required large quantities of nitrogen for their new shipping terminal. CGT worked closely with one of the world’s largest engineering companies located on Houston to supply the most efficient nitrogen system possible. After the nitrogen generator equipment was manufactured; installed; and commissioned the engineering firm commented on how well CGT was not only able to meet all the equipment specifications but also the documentation requirements for the project.