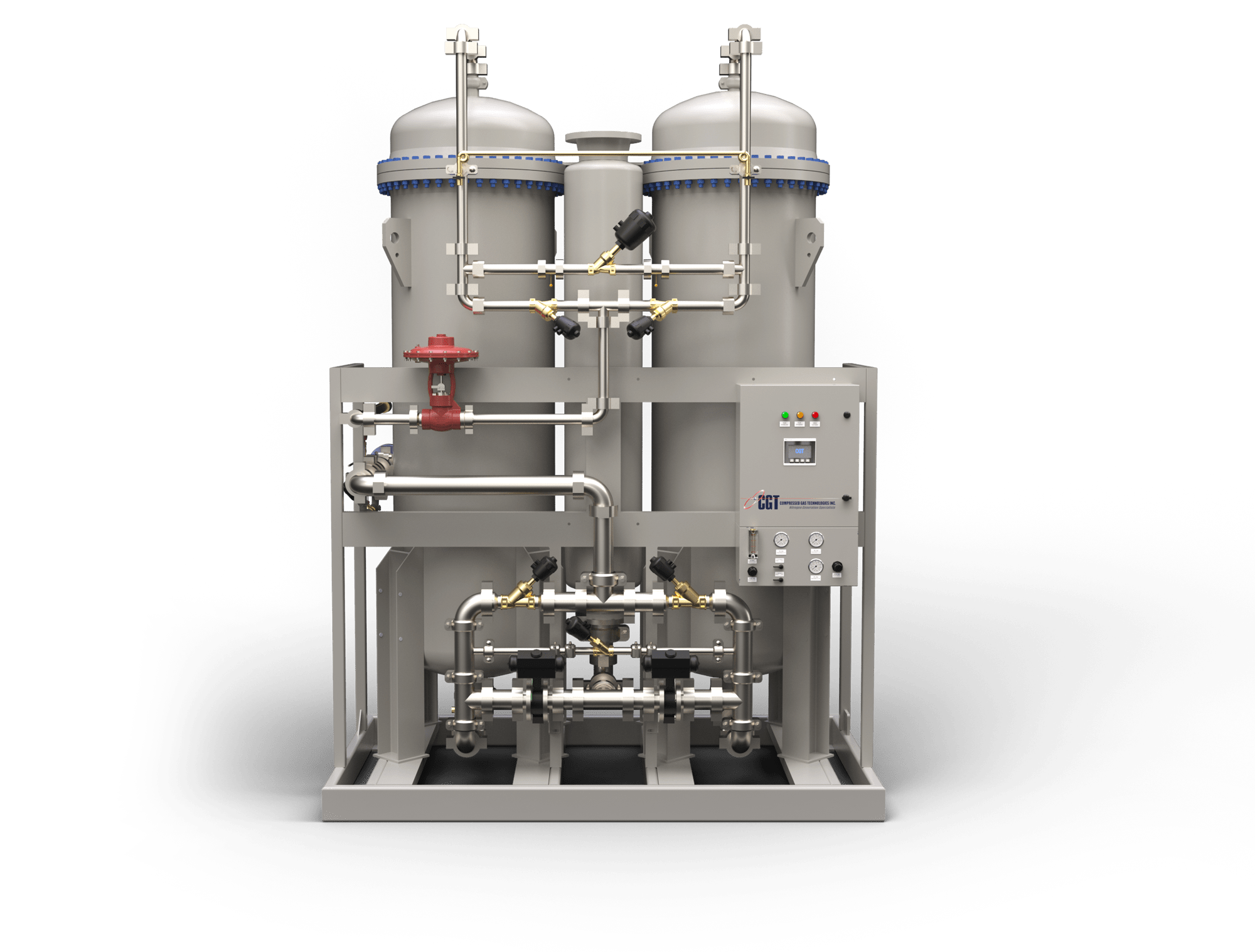

[dropcap]Compressed Gas Technologies Inc. nitrogen generators cover a wide range of flows and purities to exactly match the needs of applications including LCMS, GC, ICP, ELSD / CAD detector, Circular Dichroism and Sample Evaporation. The optional Generators incorporating an integrated oil free compressor completely eliminate any reliance on a house compressed air supply giving complete security of supply.

[dropcap]Compressed Gas Technologies Inc. nitrogen generators cover a wide range of flows and purities to exactly match the needs of applications including LCMS, GC, ICP, ELSD / CAD detector, Circular Dichroism and Sample Evaporation. The optional Generators incorporating an integrated oil free compressor completely eliminate any reliance on a house compressed air supply giving complete security of supply.

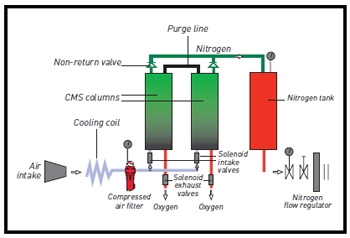

The technology used to procure a continuous flow of high purity nitrogen is pressure swing absorption ( PSA ). This technique uses one or two carbon molecular sieves beds (CMS) to eliminate oxygen and other contaminants in the ambient air selectively.[/dropcap]

Benefits of Lab Gas Nitrogen Generators

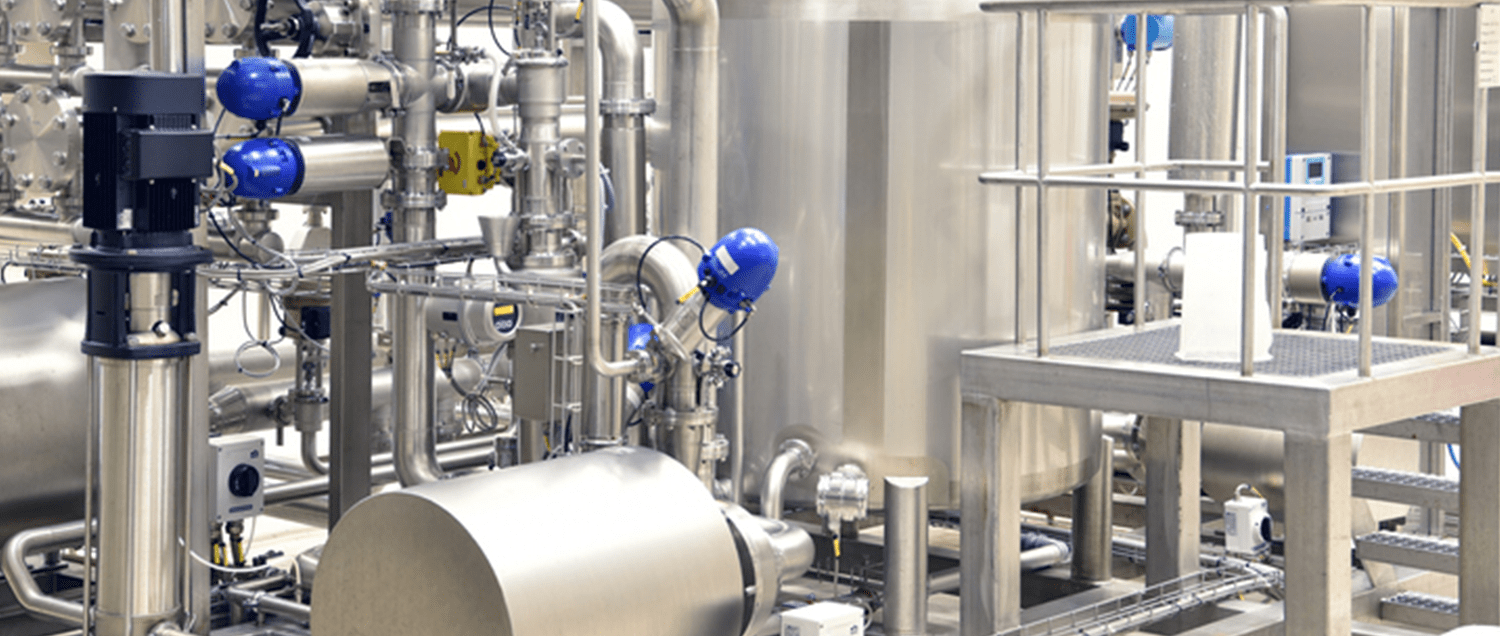

- Designed to meet specific analytical instrument gas purity and flow requirements

- Improved analytical performance – Production of a constant flow of gas improves the consistency of the analysis results and hence reproducibility

- Increased laboratory efficiency with a constant, guaranteed supply

- Improved safety – No handling high-pressure gas cylinders or liquid dewars. Nitrogen production at controlled low pressures

- Simple installation – Only one set up operation required for reliable service over time. Installation on or below a laboratory bench top, saving space in the laboratory

- Economy – Quick return on investment – No gas cylinder rental bottles, no price inflation

- Recommended by major instrument manufacturers

Technical Features of Lab Gas Nitrogen Generators

Principle: passage of compressed air through a bed of carbon molecular sieve (CMS) using press ure swing adsorption technology, the most reliable on the market

[one_half]

- N2 flow: 550 cc/min to 30L/min (for larger capacities please contact us directly)

- O2 purity: 3% to 10 ppm

- On-line purity monitoring capability

- Digital hours counter. Audible and visual maintenance indicator

- Economy mode option: Enables the compressor to switch off when nitrogen supply is not required

- Oil-free air compressor available: The quietest models available

- Available with or without built-in air compressor

- Quick and easy servicing: less than 10 minutes every 6 months

- A 25L/min version is also available

[/one_half]

[one_half_last]Quick Estimate[/one_half_last]

How Lab Gas Nitrogen Generators Work

The technology used to produce a continuous flow of high purity N2 How Lab Gas Nitrogen Generators Work is pressure swing adsorption (PSA). This technology uses a combination of molecular sieves to selectively eliminate O2 and other contaminants in the ambient air. The CMS column(s) alternate between the purification and regeneration modes to ensure continuous N2 production. The gas generator is designed to take pre-filtered compressed air at 7 or 8.5 barg (102 or 123 psi g) (depending on model) from the existing laboratory supply or via the integrated oil-free compressor.

The technology used to produce a continuous flow of high purity N2 How Lab Gas Nitrogen Generators Work is pressure swing adsorption (PSA). This technology uses a combination of molecular sieves to selectively eliminate O2 and other contaminants in the ambient air. The CMS column(s) alternate between the purification and regeneration modes to ensure continuous N2 production. The gas generator is designed to take pre-filtered compressed air at 7 or 8.5 barg (102 or 123 psi g) (depending on model) from the existing laboratory supply or via the integrated oil-free compressor.

This flow of filtered compressed air then passes through the CMS column which is in the purification mode. At this point, the O2, CO2, humidity and hydrocarbons are eliminated from the compressed air, producing a flow of clean and dry high purity nitrogen. For zero N2 generators, a heated catalyst oxidizes additional hydrocarbons from the N2 gas flow providing zero grade N2 with a remaining hydrocarbon content of <0.1ppm.