Benefits of using a membrane nitrogen generator

Complete control of N2 supply can only be achieved when a business produces its own nitrogen gas, allowing you to meet a nitrogen requirement and achieving self-sufficiency from the nitrogen generation and supply chain. Besides the typical installation of a sizable cryogenic air separation plant, there are two other ways of generating nitrogen yourself: these include membrane nitrogen generators and PSA generators. This article will discuss how a membrane nitrogen generator works and the advantages of a membrane nitrogen generator.

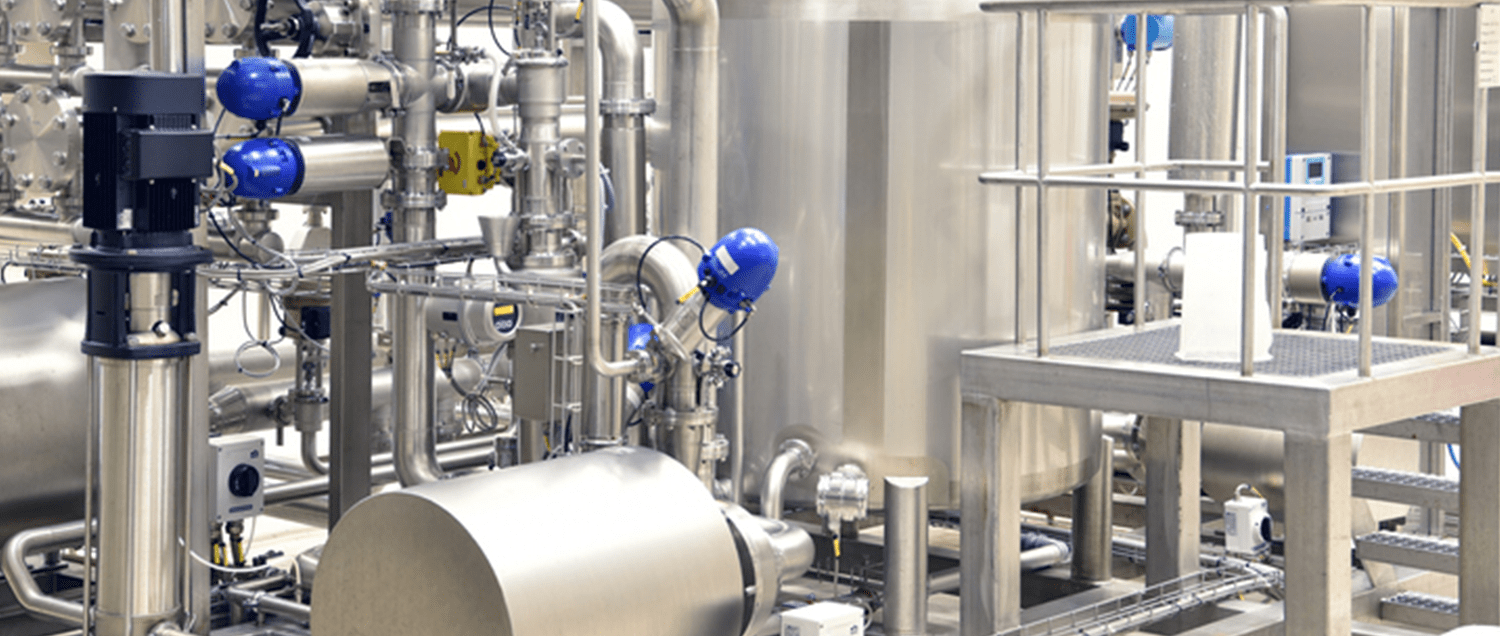

Membrane nitrogen generators work based on a simple principle. The membrane module is the main part of the generator, approximately 10cm in diameter, and is filled with tiny hollow fibers of a polymer. Clean, dry, compressed air enters the fibers and flows towards the outer side of the fibers in a process called permeation. Simultaneously, water, oxygen, and argon exit through the sides of the fibers membrane. Ultimately, only nitrogen remains due to the capability of different molecules permeating at different speeds.

What are the advantages of a membrane nitrogen generator?

Membrane nitrogen generators are reliable. These membrane nitrogen generators provide a steady stream of pure, dry nitrogen that is immediately ready to use for the intended industrial applications it was produced for. Some other prominent advantages of membrane nitrogen generators are:

- Initial capital cost is low considering the purity level achieved by the generator. An onsite membrane nitrogen generator cuts down the recurring expenses of cylinder rental, supply, delivery, and manual handling.

- It is best suited for industrial applications requiring gas purity to be lower than 99.5%. Similarly, the purity of nitrogen can be controlled by the operator to work the business-specific application needs.

- You can start the generation of gas in a few seconds. The engineer can regulate the flow rate of the gas to fit the specific needs of the application.

- Almost 100% of gas produced in these generators can be used compared to the 5-10% wastage in cylinders.

- The maintenance is low-cost. If properly maintained, the generators can function for up to 10-15 years.

- The generators are modular in design, and you can achieve future expansion by adding a membrane module to an existing generation system. Also, these generators are compact and portable, which takes up less floor space. The small, unchanging design footprint ensures it can fit in small areas.

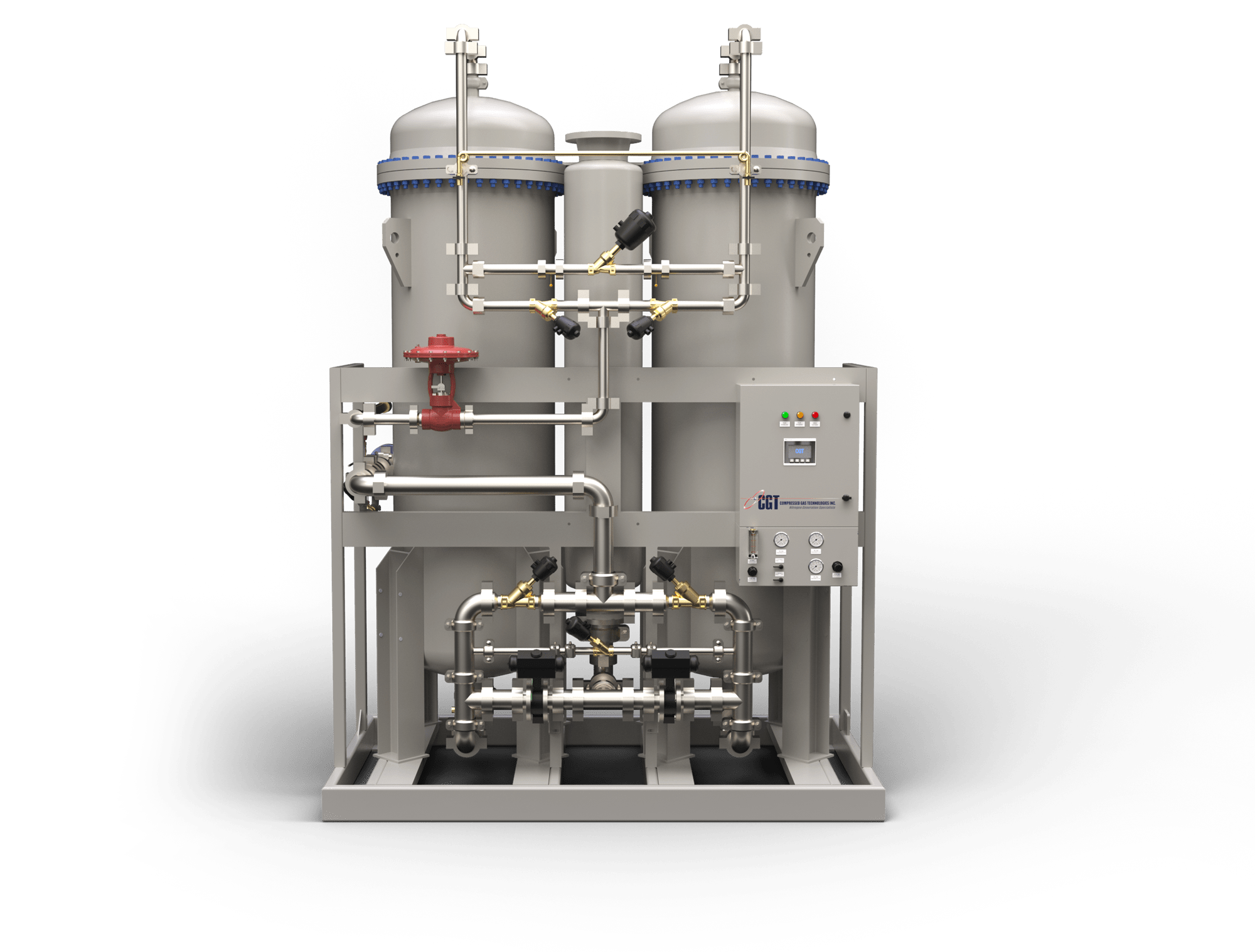

For a complete turnkey nitrogen solution, you should choose Compressed Gas Technologies high-volume, high-capacity membrane nitrogen generators. Our generators are designed to precisely fit onsite and provide continuous, uninterrupted, extremely pure nitrogen to fulfill our clients’ business needs.

CGT’s onsite membrane nitrogen generators are the only solution to replace clunky-clanky nitrogen cylinders that waste precious time due to delayed deliveries. Visit our website or call our expert technicians who can help to clarify which onsite nitrogen generator is right for your business.