Tag Archives: benefits of on-site nitrogen

Major gas supplier announces second price increase in 3 months!

Air Products recently announced they will be increasing pricing for bulk liquid nitrogen effective January 1st, 2019. This is the second increase in the last 3 month...

Nitrogen Generator for Pizza Packaging Line

One of the largest pizza chains in the United States recently installed a CGT high purity nitrogen generator to supply food-grade nitrogen for their new packaging li...

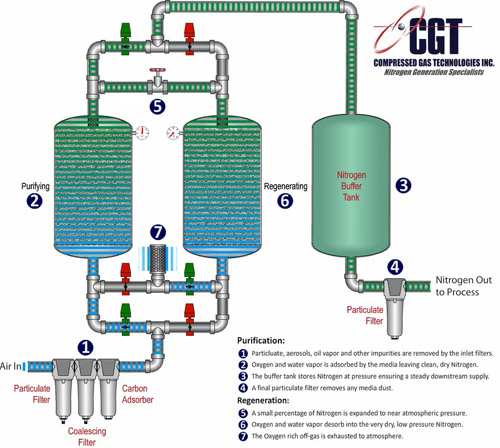

On-Site Nitrogen Production

How On-Site Nitrogen Works

The air we breathe is roughly 78% nitrogen and 21% oxygen. By simply taking atmospheric air and compressing it to >100 psig, we can th...

Benefits of On-Site Nitrogen

Is On-Site Nitrogen Right for You?

If you are currently using nitrogen for tank padding, drying, product transfer, purging, flushing, inerting, you should then lo...