Pizza, Cheese and The Super Bowl

New Year’s resolutions face the first serious test of the young year on February 1st when the Seattle Seahawks and New England Patriots battle it out in Glendale Arizona. Besides becoming a de facto American holiday, Super Bowl Sunday has also claimed the second spot in single day food consumption, behind only that most venerable of victuals celebrations – Thanksgiving.

According to a Nielson poll, 2014’s top prize for most consumed game day hot food (excluding things like chips and dips) was pizza. ‘Za climbed the charts from 2013 to beat even the high flying chicken wing with the top three U.S. Chains slinging 4 million pies during the big game.

While pepperoni, sausage, and mushrooms hold the top spots for the spots on top, it’s all held together with mounds of gooey cheese. In fact, pizzerias spend some $4 billion on the stuff each year. That’s a lot of bags of shredded cheese, all with varying susceptibility to spoilage when confronted with oxygen.

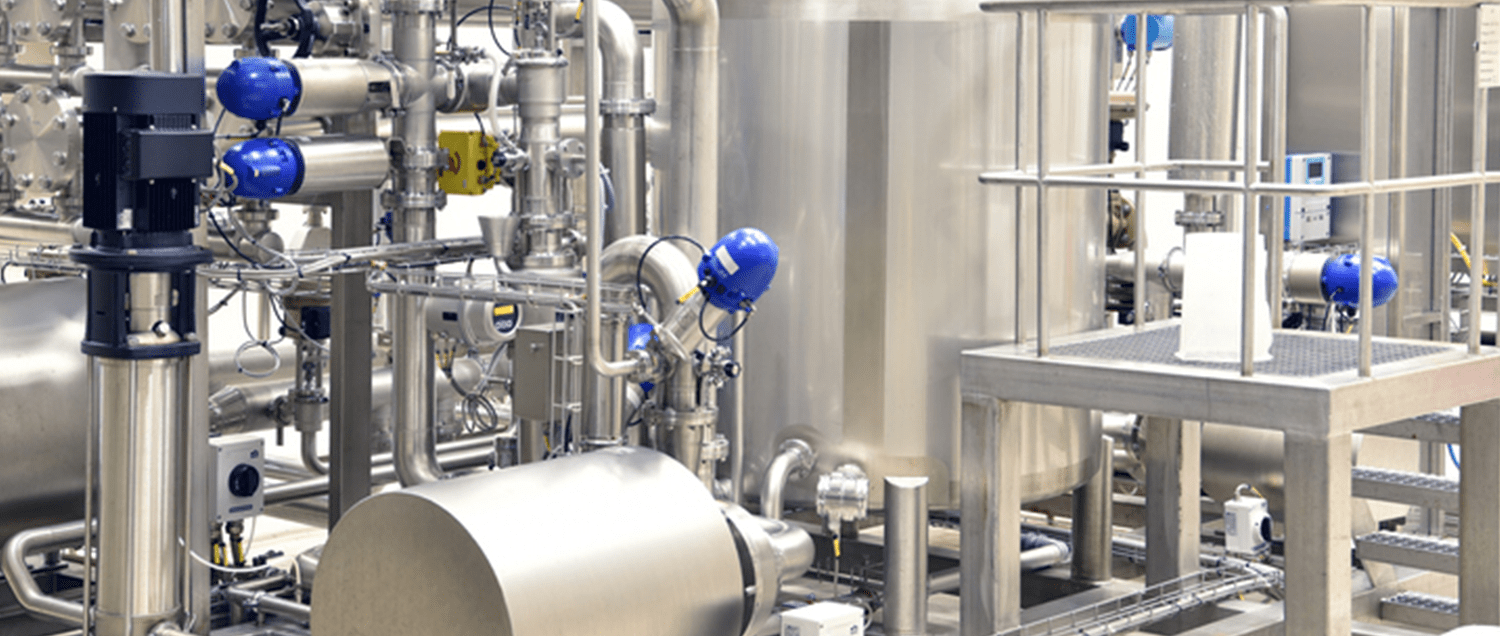

That’s why so many companies use a modified atmosphere while packaging shredded cheese. By introducing a mixture of carbon dioxide and nitrogen the amount of oxygen is reduced in the bag, reducing spoilage and increasing shelf life.

Of course, like any utility, the cost of purchasing gasses like nitrogen can sometimes overwhelm the benefits of using them. Large packagers find themselves faced with bills in the 10’s and 100’s of thousands of dollars each year, just for N2.

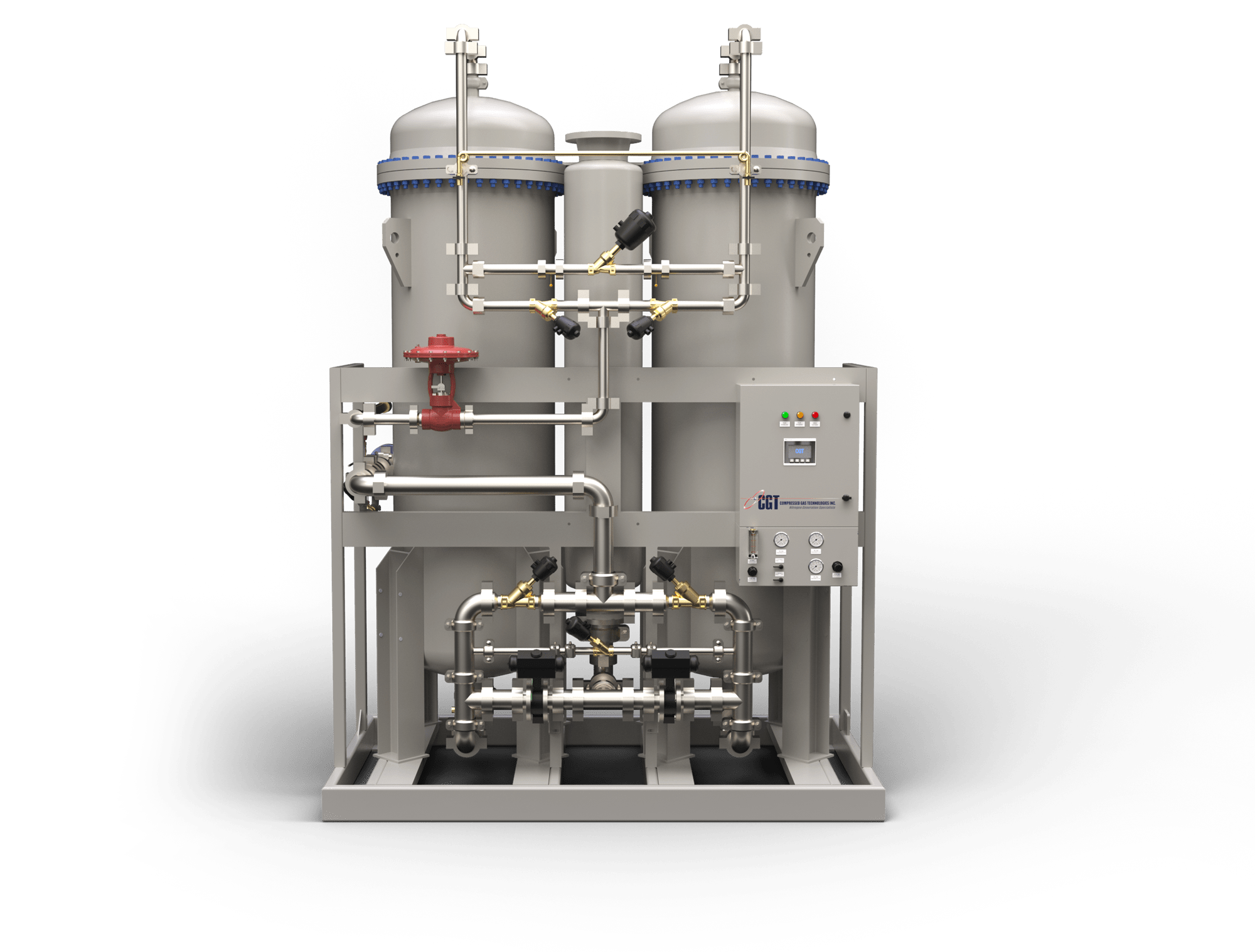

For those looking to extend shelf life and avoid succumbing to another hefty utility bill, nitrogen generators have become a welcome alternative. Since generators are simply separating oxygen from a stream of compressed air that’s already at the factory, a generator can supply a constant, clean supply of N2 as soon as it’s needed – a delivery record every pizza guy can respect. And at a cost that’s 60% to 75% less than nitrogen from a gas company, packagers are saving a lot of cheddar on their mozzarella.

Delivering the right nitrogen for cheese packaging isn’t easy as pie. The modern gas mixers used to combine N2 and CO2 may require minimum flow rates and higher pressures than other food packaging applications. It’s important to start with a group that’s experienced in the practice of producing nitrogen locally. Compressed Gas Technology has worked with several of the biggest names in the industry over the past 13 years and has the experience to make the right call.

Now, as for those new-year’s resolutions: www.nyc.gov suggests that one piece of pizza is the proper serving size. But remember, if you don’t cut it, a whole pizza is still one piece.