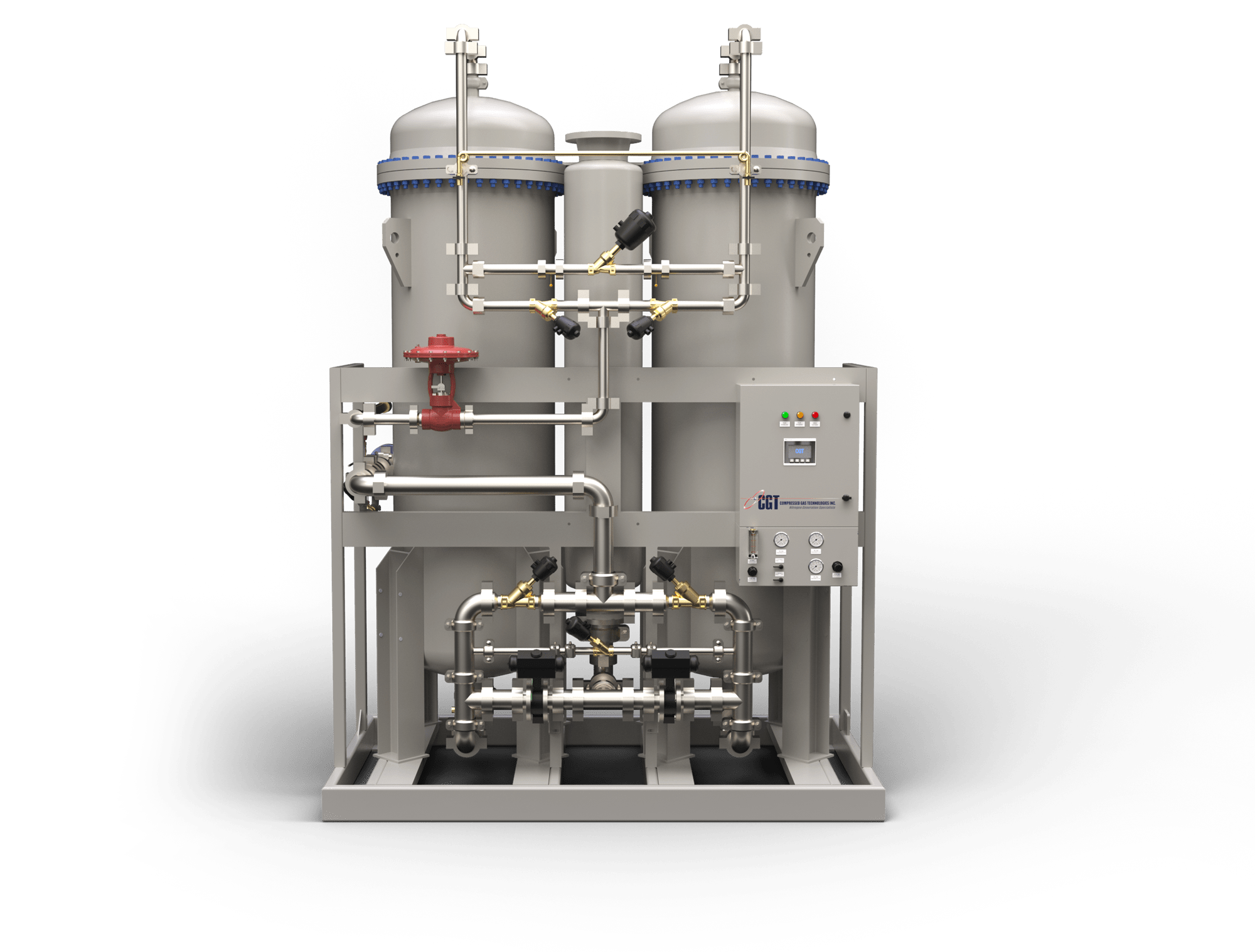

Nitrogen Generator Maintenance

[dropcap]Your nitrogen generator has been up and running now for six months. In order to keep your nitrogen generator working efficiently, you should schedule in nitrogen generator maintenance into your process schedule to ensure optimal performance of your generator.[/dropcap]

Most nitrogen generators require maintenance every six months (check your manual for specific maintenance intervals – always follow recommended operating procedures when operating the equipment).

First, clean the equipment with a damp cloth only avoiding any contact with electrical components. Next check the status indicators/ gauges on the front control panel to ensure the unit is functioning properly. Check for any leaks as well as the inlet air quality. Once this has been done shut the unit down according to the manufacturer’s shutdown procedure.

Many nitrogen generator manufacturers use a combination of both coalescing and carbon filtration. Simply follow the instruction in the manual to change the filter elements.

Next, if you have a PSA (Pressure Swing Adsorption) nitrogen generator system, you will need to replace the muffler. Discard of the filter elements and muffler according to your company’s waste disposal process.

Valve replacement and oxygen sensor replacement will take place every three years typically, depending on hours of operation for the nitrogen generator. It is usually recommended that a factory trained service technician performs this procedure.

Once the maintenance items have been changed, restart the equipment based on the manufacturer recommended start-up procedure.

Nitrogen generator maintenance is required every six months and by simply following these easy maintenance steps your nitrogen generator should provide you with a continuous supply of clean nitrogen gas for many years to come.

Compressed Gas Technologies can answer all your questions about nitrogen generator maintenance – contact us!