How Nitrogen Generators Benefit the Fruit Storage Industry

What Does the Fruit Storage Industry and Nitrogen Generators Have in Common?

[dropcap]Everyone loves fresh fruit in the summer months. But when the weather turns and local fresh fruits are no longer an option then -fruit storage containers are used by the industry. The fruit storage industry allows us all to have fresh crisp fruit all year long.

[dropcap]Everyone loves fresh fruit in the summer months. But when the weather turns and local fresh fruits are no longer an option then -fruit storage containers are used by the industry. The fruit storage industry allows us all to have fresh crisp fruit all year long.

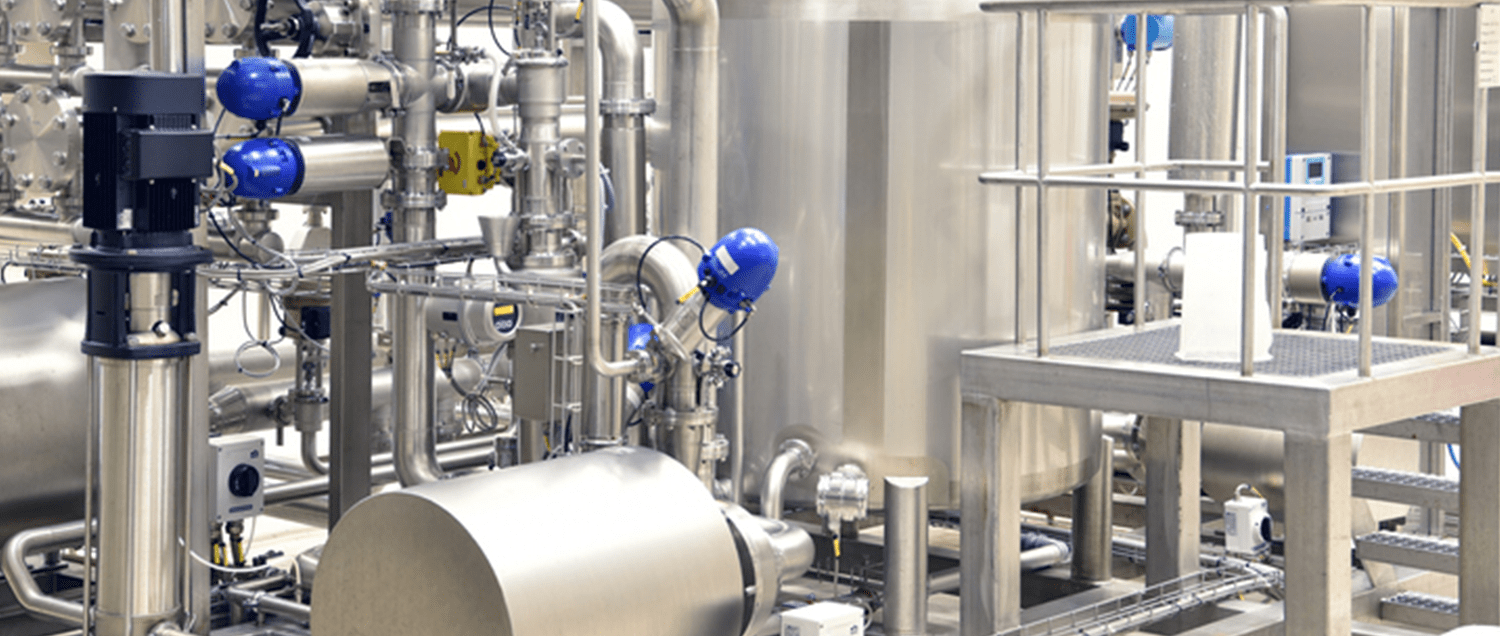

Controlled atmosphere storage (CA) involves an attentive process of controlling gases within the large storage rooms. These rooms must be sealed in order to keep fruit just as fresh as the day it was picked. Accurate control of the temperature, oxygen, carbon dioxide and humidity are all important elements in fruit storage. Controlled atmosphere storage for fruit storage is a non-chemical process. Controlling the oxygen levels in the storage containers is most successful by introducing the infusion of nitrogen gas. Nitrogen generators can assist oxygen levels from roughly 21 percent in our breathing air to as low as 1 or 2 percent. Nitrogen generators are extremely effective investments for the fruit storage industry.[/dropcap]

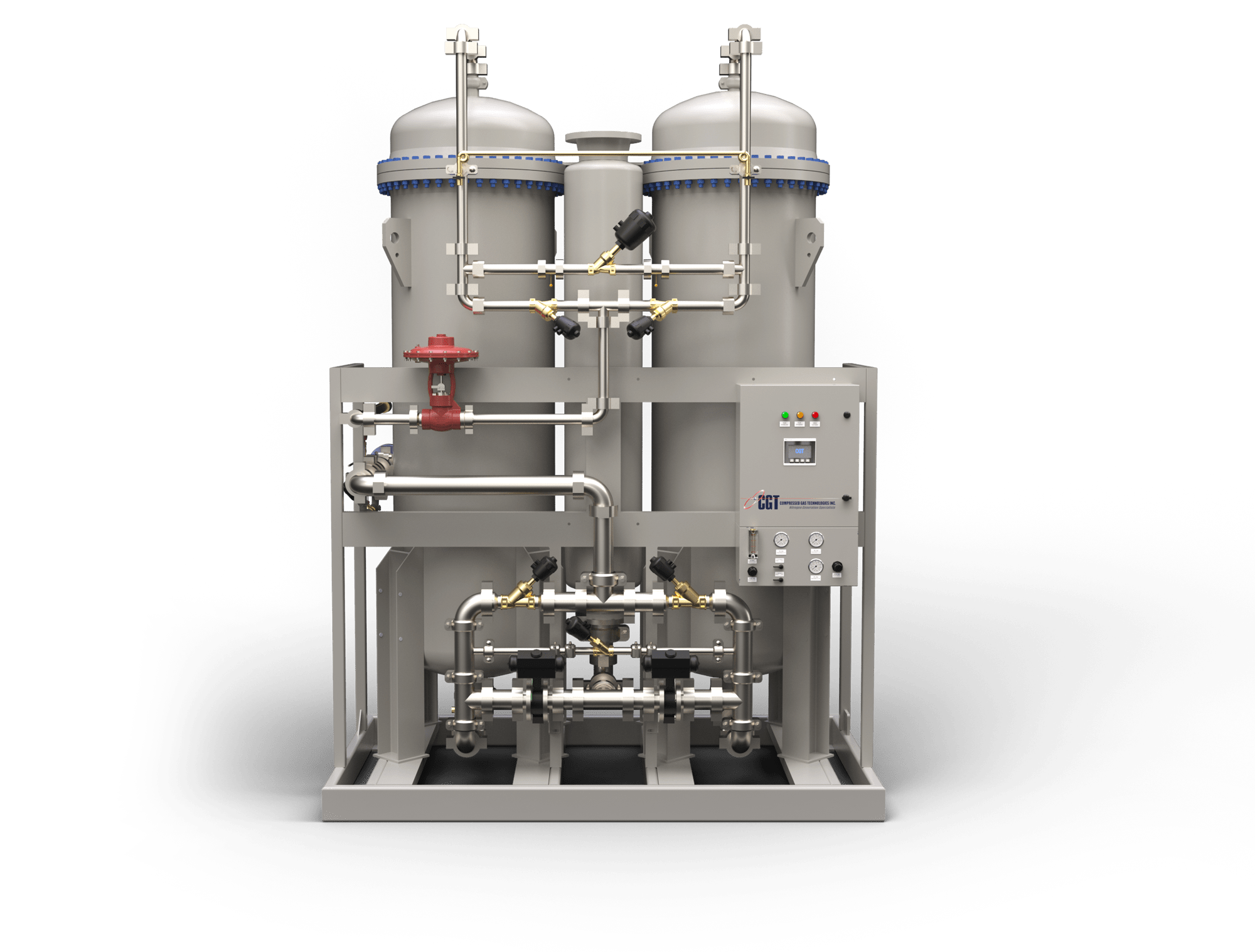

For the fruit storage industry, there are two unit types best suited for the application required. Membrane generators or PSA nitrogen generators (pressure swing adsorption). The unit you choose always depends on your specific needs. However if you are not entirely sure which generator is best suited for your fruit storage company, an experienced nitrogen generator supplier will be able to suggest a unit for you.

Membrane technology generators are best suited for on-site low flow applications where the purity is 99.5% or lower. These generators have a simple manual process control and are very quiet with low maintenance levels. Membrane technology units feature a quality air pre-treatment filtration system. Fruit storage depends on a well monitored environment which slows the ripening process until the product is ready to be removed from the controlled atmosphere storage room. Membrane technology generators are an extremely low-cost and reliable source for infusing nitrogen into the rooms.

PSA generators produce nitrogen differently – by way of a carbon sieve – and are best suited for applications in which purity should be 99.5% or higher. Compressed air flows through the carbon sieve where oxygen and any other trace gas is absorbed by the nitrogen generator. All the contaminants that are absorbed by the generator are expelled after a pre-set time. An advantage of PSA units are that they have narrow pore opening within the towers. Because oxygen molecules are smaller than nitrogen molecules, the oxygen has a better chance of being absorbed into the carbon sieve and separates them from the nitrogen molecules which are much larger and can’t pass through the carbon sieve – increasing nitrogen production.

Depending on what your application needs specifically, both membrane technology and pressure swing adsorption units are great options for the fruit storage industry allowing controlled atmosphere storage rooms to operate at optimal performance levels to produce the best quality product.

For more information regarding how nitrogen generators can help the fruit storage industry – contact us!