Slashing Sticks at the Winter Classic

Players competing in Washington DC’s National’s Park are typically outfitted with baseball bats and cleats. But on January 1st, 2015, fans crowding into the park will cheer for athletes shod in skates and brandishing hockey sticks as the hometown Capitals take on the Chicago Blackhawks in this year’s NHL Winter Classic.

The Classic, a regular season hockey game played at outdoor venues around the U.S., first took place in Pittsburgh in 2008. The strong response, the Winter Classic has garnered some of the highest TV ratings in NHL history, has solidified it as a pinnacle event in the regular NHL season for years to come.

While those sticks the ‘Hawks and Capitals will wield on New Year’s day will mostly be constructed of carbon fiber and other composites, in the 80’s and 90’s aluminum was the material of choice. The high strength to low weight ratio aluminum provides still makes it an ideal option for all sorts of products from bridges to buildings to aircraft.

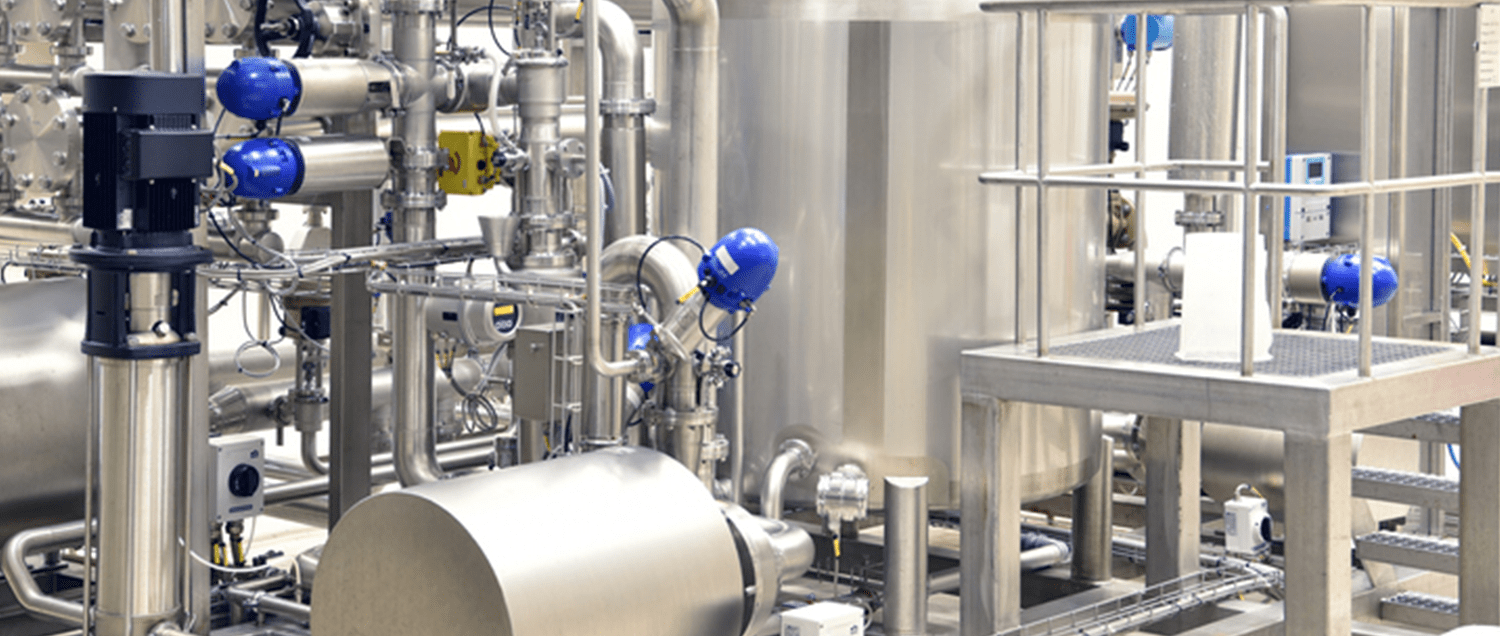

When strength is key, cast aluminum cannot have imperfections. Inclusions, pockets of coalesced hydrogen in molten aluminum, are one of the most common imperfections a foundry operator needs to deal with. Hydrogen is leached from atmospheric humidity on the surface of the molten metal. As the metal cools the hydrogen gathers into pockets – traveling from areas of high pressure to areas of low pressure. These pockets create a weak spot in the finished product.

A popular method used by many aluminum foundries to remove hydrogen from liquid aluminum is through the introduction of nitrogen gas. Hydrogen atoms are picked up by bubbles of N2 as they travel through the pot of molten metal and released on the surface.

The downside of this procedure is the management of delivered nitrogen. Cylinders of gas run out and skilled operators need to leave their station to replace them. The supply of N2 requires constant management and if the site runs out of gas an entire line can shut down.

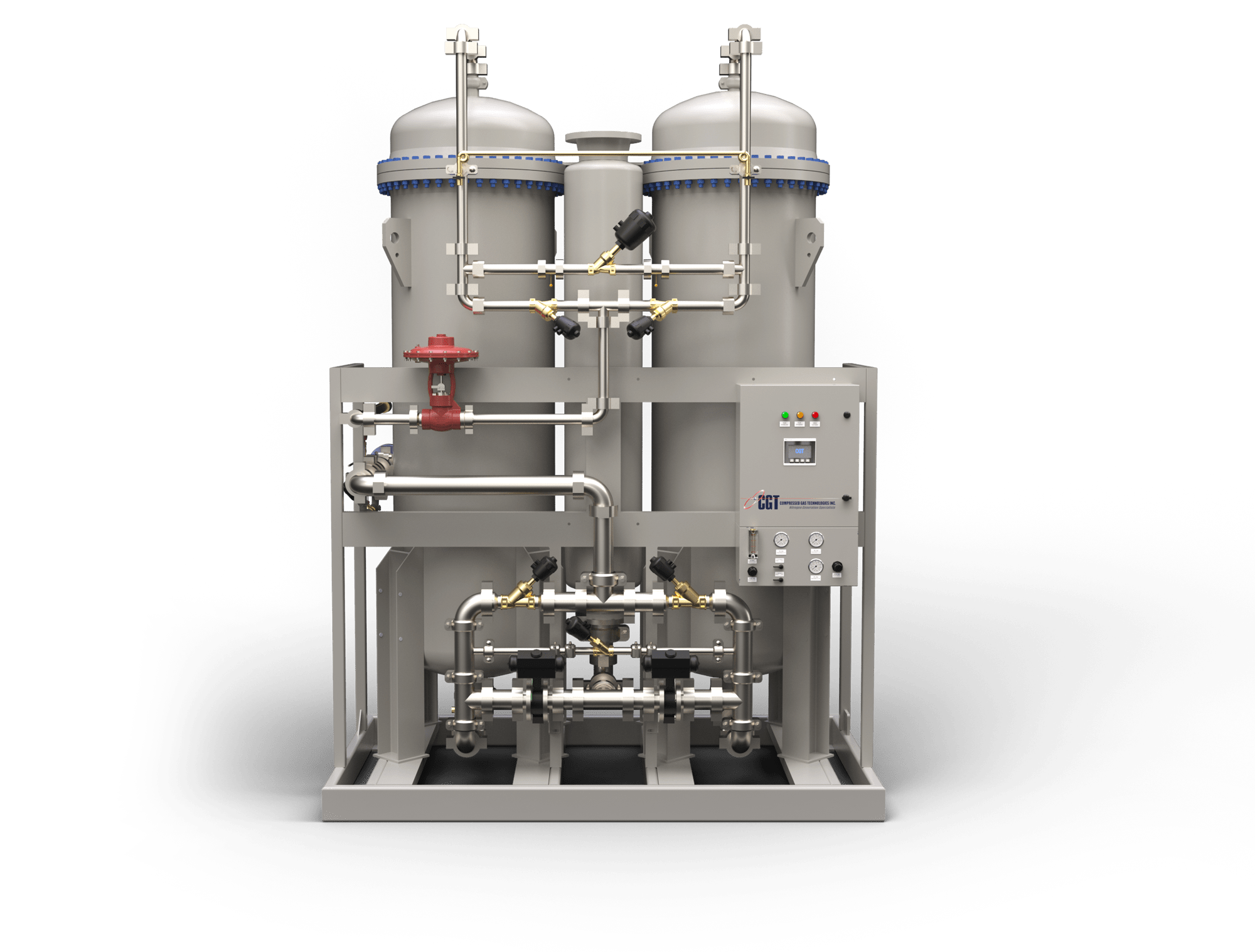

More frequently, foundry managers are turning to nitrogen generators. A generation system separates oxygen and other impurities from a standard supply of compressed air. Most systems require only simple maintenance every 6 or 12 months so busy foundries can spend more time focusing on producing high quality products.

The most important step when switching to a self-generated supply of nitrogen is designing a system capable of producing the right flow and purity for the application. Working with a group that has focused on the production of in-house nitrogen for a long time is key to the success of this process. Compressed Gas Technologies has more than a decade of experience designing systems for all sorts of applications, including aluminum degassing.