Blog

Protect the Planet and Your Bottom Line with Nitrogen

On April 22nd cities around the world will take part in one of the largest global environmental movements ever organized. Celebrating its 45th anniversary, Earth Day festivities will reach nearly every corner of inhabited land on the planet.

In Osijek Croatia, a street festival will carry a message about recycling more reusable products. A dedicated group of volunteers will work to protect the Usambara Mountains in Tanzania. Iraqi’s concerned about their homelands future will plant olive trees. And at the Great Wall of China hundreds of concerned hikers will clean up trash, reversing the trend of years of neglect by the site’s visitors.

The Earth Day we celebrate today began in 1970 after Gaylord Nelson, U.S. Senator from Wisconsin, witnessed the devastating effects of an oil spill off the cost of California. Through his work, and the efforts of a bi-partisan group of concerned lawmakers, Earth Day was born. The Clean Air Act, the Clean Water Act and the Endangered Species Act all came about as a result of their early work. For his part, Nelson would win the Presidential Medal of Freedom in 1990.

Twenty million people, many from grade schools, high schools, and universities participated in that first event. This April 22nd hundreds of millions of people from 192 countries will take part in Earth Day.

Thousands of companies across North America will help make Earth Day 2015 a day to remember. From switching to recycled packaging to installing solar panels to motivating their workforce to volunteer in their communities, these forward thinking groups work to make a difference.

But sometimes the balancing act between “going green” and running a profitable business can make it difficult for even the most environmentally conscience facility. It’s rare that a company has an opportunity to both protect the planet and their bottom line. But for groups using lots of nitrogen in their process, such an opportunity exists.

Nitrogen is used for a variety of applications such as food packaging and chemical blanketing. The traditional way to obtain a source of nitrogen is to purchase it from a gas company. Gas companies produce this product through an energy intensive cryogenic process. The resulting nitrogen is either stored in individual cylinders or pumped, as a liquid, onto large tanker trucks. In both cases, the nitrogen is then delivered to each facility that needs it.

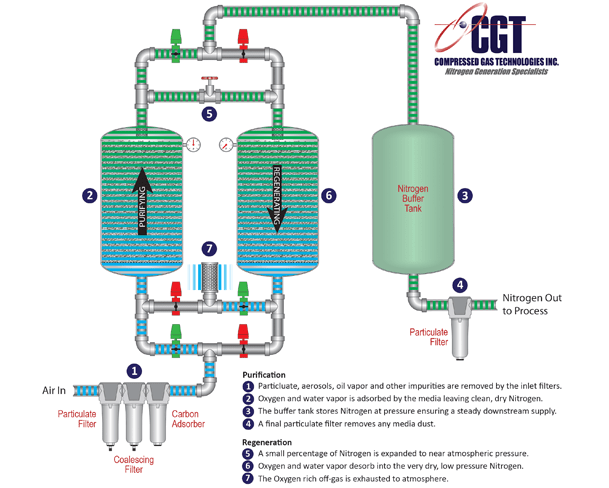

The alternative to the delivered supply is a gas generator located at the site of use. Using either a membrane or carbon molecular sieve, the generator separates naturally occurring nitrogen from a compressed air stream, providing a constant supply of gas. When compared to producing nitrogen cryogenically and traveling long distances, the resulting carbon footprint of a nitrogen generator is much less than a delivered supply. And for a facility that needs a constant supply of nitrogen for more than a year, the cost to produce it on site is also greatly reduced.

Any switch in technology is best done with the help of an expert. The team at Compressed Gas Technologies has helped hundreds of companies save money and improve the sustainability of their nitrogen supply.