Blog

How Nitrogen Gas Benefits the Food Packaging Industry

In the following we will aim to help explain how on-site nitrogen gas benefits the food packaging industry in preserving freshness, food quality, and integrity through this article.

1. Properties of Nitrogen gas:

Nitrogen gas is unique, and its physical properties make it the most suitable for food processing. Nitrogen gas is inert in nature, does not react with food materials, and preserves aromas and flavors. It is excellent at effectively displacing other gases that cause oxidation or support the growth of microorganisms.

2. FDA Approval for use in food packaging:

Nitrogen gas is approved and used under good manufacturing processes. The FDA approves its use and considers nitrogen as a GRAS gas ‘Generally Recognized As Safe.’ This means nitrogen flushing used in food packaging is deemed safe for you.

3. Product shelf life increases:

Bacteria require oxygen to thrive. Purging food packaging with nitrogen gets rid of the oxygen, and there is no way for mold, mildew, or harmful bacteria to deteriorate the product once it exits your facility.

4. Maintains the food quality:

Moisture can destroy a food product. Nitrogen is dry, and it occupies the entire vacant space within a food package. This ensures there is no chance of moisture entering, and hence you need not worry about the food getting destroyed due to this.

5. It ensures the integrity of the food product:

Products like wafers, potato chips, and other food items break due to friction caused when the package is in transit. Nitrogen acts similar to a buffer and provides an in-built barrier to keep food items intact during transit.

6. Create a pressurized atmosphere for efficient packaging of food:

Oxygen is known to deteriorate food items due to oxidative rancidity gain or loss of moisture. However, nitrogen gas is a clean gas, inert and dry in nature. Upon adding nitrogen gas to the packaging, oxygen is removed in the process. This process of purging food packaging with nitrogen to eliminate oxygen helps to keep the produce fresh for an extended period.

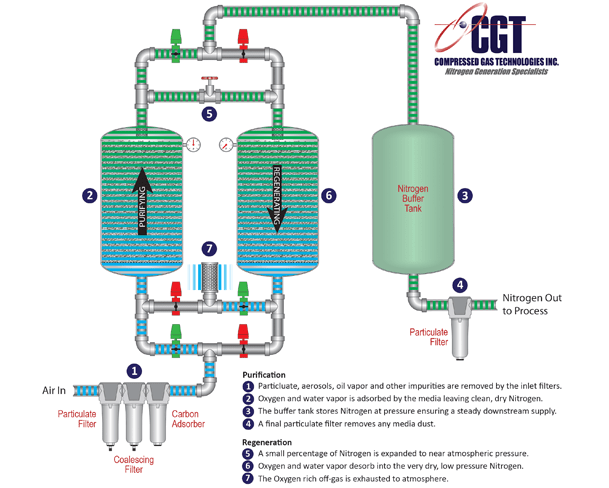

7. Improvement of packaging with on-site nitrogen generation:

On-site nitrogen generation easily replaces the traditional buying of bulk cylinders to sustain food manufacturing, processing, or packaging. On-site generation of nitrogen empowers businesses to no longer depend on costly delivery, storage, and supply of nitrogen. It also saves a lot of money that you can use to scale the business further. An on-site generation of nitrogen for the food packaging industry also ensures that the company controls gas purity and is specific to their requirements.

CGT has vast experience designing, installing, and servicing nitrogen generators for food packaging businesses. Our equipment is designed to fit the specifications and space of clients. Similarly, we can provide nitrogen generation systems to fit single pouch packaging or large vegetable oil refineries.

To speak with us or to get a free estimate, call CGT today! Our experts will quickly assist you with determining system size, requirement, and a price for an on-site nitrogen generator.