How Nitrogen Generators Assist in Precision Laser Cutting

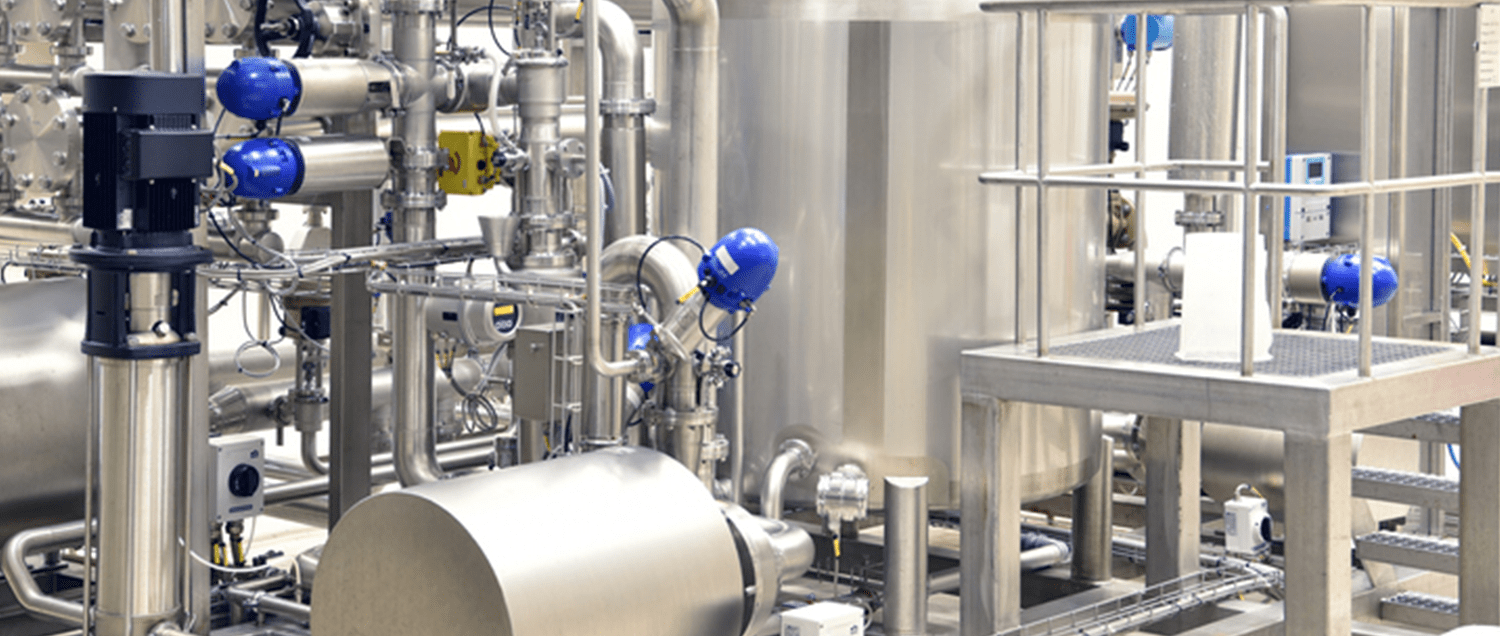

Laser cutting is a process where metals like stainless steel and aluminum are cut for industrial and commercial uses with a high-powered, precision laser beam. Typically, an assist gas is used to help the laser deliver clean cuts and perform at its very best. Selecting which gas to use depends on certain factors such as the type of material being cut, the required quality of the cut and the thickness of your material.

Today, the most common type of assist gas for laser cutting is nitrogen. It is the gas that is most frequently used as it offers several advantages during the laser cutting process. For instance, a nitrogen assisted laser can cut through metals without burning or discolouring the material unlike when another gas such as oxygen is used to assist. Additionally, nitrogen gas has the unique ability to vaporize the metal away from the cut edge before it has the chance to re-solidify, providing you with a cleaner cut and therefore, improving the quality of your final product.

Laser Cutting Nitrogen Applications

While the initial costs of nitrogen laser cutting may be slightly higher than oxygen powered laser cutting, using nitrogen as an assist gas can deliver a product that does not require any additional finishing, saving you money in the long run. Here are a few examples of laser cutting nitrogen applications:

- Mild and Stainless Steel: For mild and stainless-steel applications, maximum oxidization is typically required. While oxygen powered laser cutting has limited cutting speed, its nitrogen counterpart can generate a higher power to result in faster cutting. Therefore, nitrogen is extremely suitable for this particular application since it can cut faster and more precisely than any other alternative.

- Plasma Cutting Steel: If you are seeking a clean-cut and weld-ready edge, plasma cutting is the way to go. When nitrogen is used as the assist gas in this application, it enables a quick and clean cut that doesn’t require further processing. Conversely, using oxygen as the assist gas can introduce contaminants that result in oxidation which may be difficult to clean.

- Plasma Cutting Aluminum: Compressed air may be the most affordable option but using oxygen is not the most suitable for this application. Therefore, when working with thinner metal applications such as aluminum, nitrogen is the best choice in terms of cost, quality and cutting speed.

Browse Our Nitrogen Generators for Laser Cutting at Compressed Gas Technologies Inc

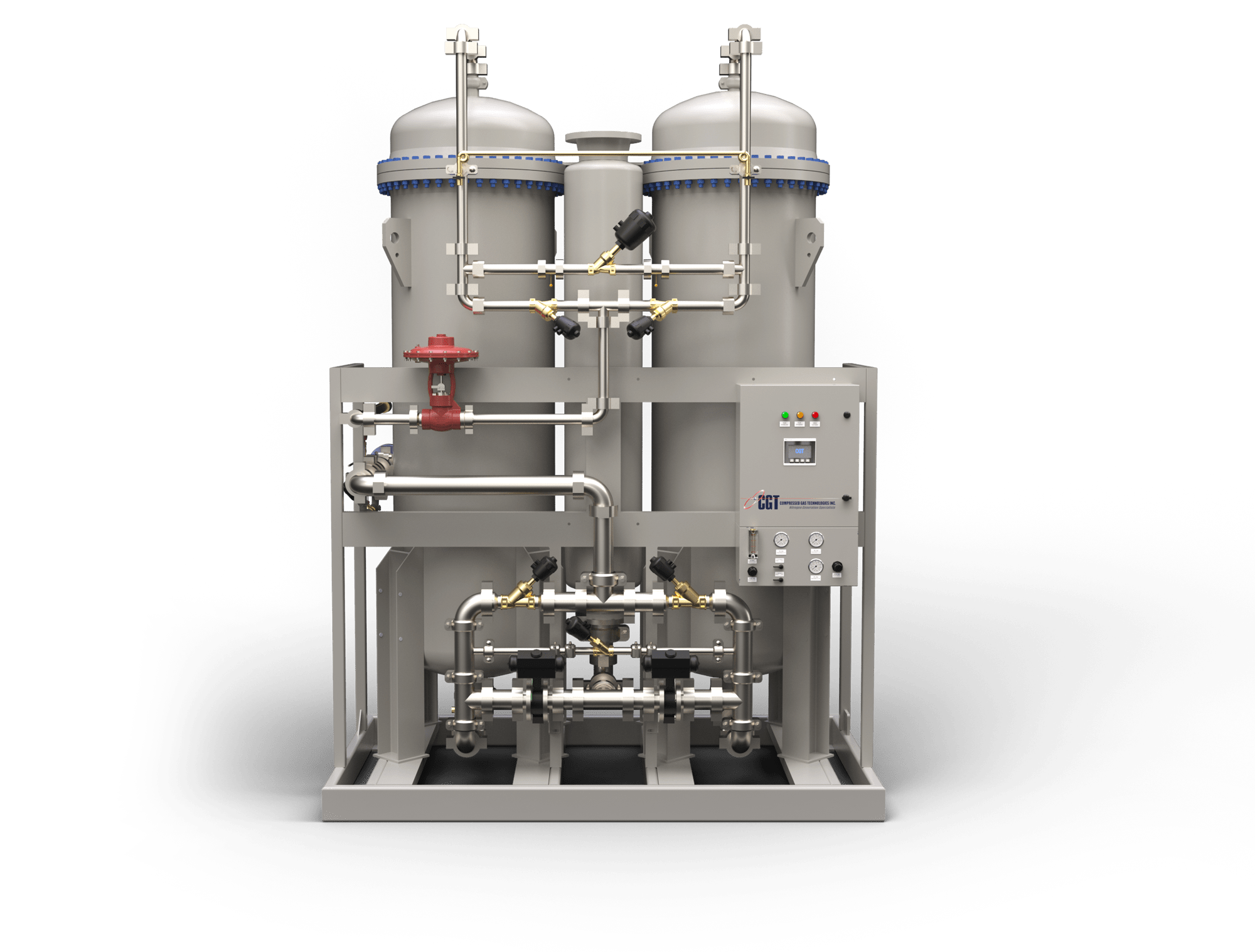

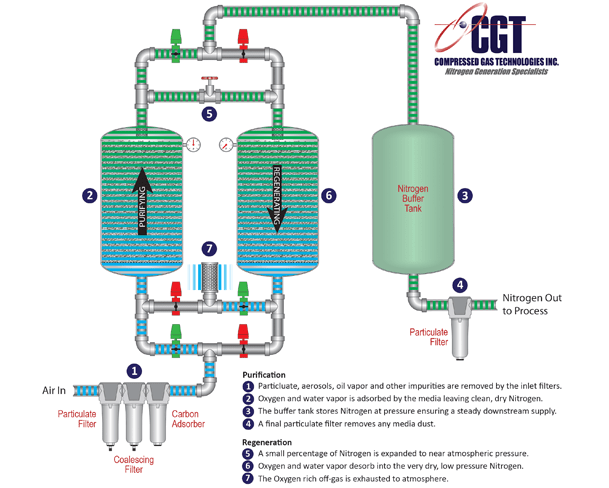

Nitrogen laser cutting offers extreme versatility and produces a higher quality product versus an oxygen powered alternative. If you want to install a better and more affordable source of nitrogen, get in touch with the nitrogen generation experts at Compressed Gas Technologies Inc. We offer on-site nitrogen generators that deliver pure nitrogen in the quantity you want and at the precise moments, you need it. Our Membrane and Pressure Swing Adsorption (PSA) nitrogen generators are designed with your application in mind and work by using the surrounding air to produce pure nitrogen gas that is able to support your metal fabrication efforts on-site. As a result, with your own nitrogen supply, you will never run into issues related to a broken supply line or mishandled fuel deliveries. To learn more about our nitrogen generation systems, speak with one of the members on our team who can help you find the right solution for your business.

For all Canadian and US-based inquiries, please contact our office at +1 (877) 737-7760, by email at sales@nitrogen-generators.com or fill out our online form for more information about our nitrogen generation products and services.