Blog

Importance of Routine Maintenance for Nitrogen Generators

CGT supplied a high purity nitrogen generator in 2014 to one of the largest popcorn manufacturers in the world. We have bee servicing the unit every year to ensure only the highest quality nitrogen is supplied to the packaging machines. Uptime is critical for the customer so they are very diligent about doing the required maintenance every year.

Routine maintenance is very important for nitrogen generators to make sure the systems make the flow and purity required today, but also 10-15 years from now. It doesn’t take long to service a system, so make sure to add the nitrogen generator to your companies PM Program.

Related Posts

Nitrogen Solutions That Protect Water Systems

CGT recently commissioned a modular PSA nitrogen generator which will supply high purity nitrogen for a water treatment system at a University in New Brunswick, Cana...

How a UAV Defense Startup Scaled 3D Printing with On-Site Nitrogen

A California based defense startup that builds unmanned aerial vehicles (UAVs) was referred to Compressed Gas Technologies Inc by a manufacturer of 3D printers who h...

What are the industrial uses of nitrogen gas?

Nitrogen is an inert gas; suitable for a wide range of industrial applications. It covers numerous aspects of manufacturing chemicals, processing, handling, and ship...

The Importance of Nitrogen Gas in the Aerospace Industry

In the aerospace industry, safety is a major and persistent issue. Thanks to nitrogen gas, inert atmospheres can be maintained, preventing the possibility of combust...

How to Choose the Right Nitrogen Generator for Your Business

Nitrogen generation systems are used in several industries around the world, from aerospace and engineering to food packaging and more. After all, for companies that...

The Benefits of Using On-Site Nitrogen Generators in the Electronics Industry

In recent years, nitrogen gas has been frequently used in the field of electronics manufacturing. The industry is extremely complex and demands accuracy and precisio...

Using Nitrogen Generation for Coffee Industry Applications

For many of us, coffee is a staple for all those early mornings. This classic hot beverage is not only delicious, but it can also help fuel the day ahead. In order t...

Can a Nitrogen Generator Help Your Organization Be Environmentally Friendly?

On-site nitrogen generators are designed to provide you with a steady supply of nitrogen gas when you need it and thus, have quickly become a staple in many industri...

How Nitrogen Generators are Used in a Laboratory Environment

In a laboratory environment, nitrogen gas is mainly used to control a highly sensitive atmosphere. Ideal atmospheric conditions are essential for maintaining a safe,...

How Nitrogen Generators Assist in Precision Laser Cutting

Laser cutting is a process where metals like stainless steel and aluminum are cut for industrial and commercial uses with a high-powered, precision laser beam. Typic...

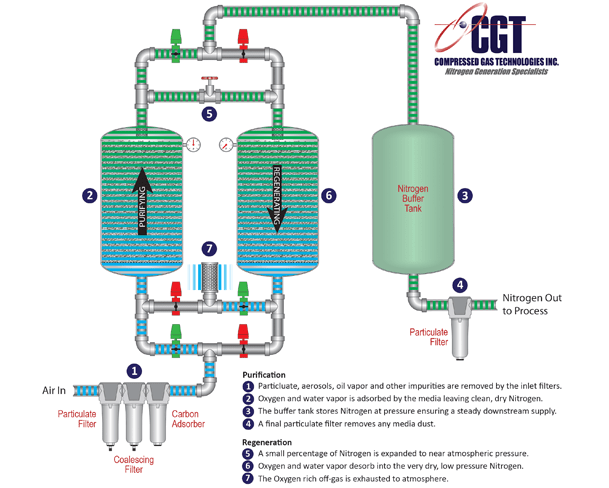

How Does an On-Site Nitrogen Generator Work?

Generating your own nitrogen rather than outsourcing it has three main advantages including lowering costs, eliminating wait time and delivering consistent purity. C...

What is a Pressure Swing Adsorption (PSA) Generator?

Nitrogen makes up a large component of the air we breathe. Thanks to on-site nitrogen generation, you can take advantage of this unlimited nitrogen source and save y...