How Does an On-Site Nitrogen Generator Work?

Generating your own nitrogen rather than outsourcing it has three main advantages including lowering costs, eliminating wait time and delivering consistent purity. Currently, there are two nitrogen generation designs available: Membrane and Pressure Swing Adsorption (PSA) Generators. As on-site nitrogen generators become an increasingly common fixture for a variety of industrial applications, you may be wondering how they work and what the benefits of different models are. While these systems are not responsible for creating nitrogen, they work by extracting nitrogen that is already present in the air around us and increase its concentration by removing other molecules such as water, carbon dioxide, and argon to reach desired purity levels.

How On-Site Nitrogen Generators Produce Nitrogen

Avoid paying on-going costs for your nitrogen supply. One of the best solutions is to produce your own nitrogen with an on-site nitrogen generation system from Compressed Gas Technologies Inc. We deliver dependable product knowledge and our customer service team is here to help answer some of the most frequently asked questions about membrane and PSA nitrogen generators. In the meantime, take a look below to learn more about how nitrogen generators work:

Membrane Nitrogen Generators

- Membrane technology is used to separate nitrogen molecules from other gas molecules such as oxygen. Dry, compressed air is filtered through a bundle of hollow porous fibres where water and gas molecules evaporate into the air, while the nitrogen gas flows through the distribution system.

- Increasing the flow of nitrogen incorporates more oxygen into the gas stream which in turn, lowers the purity of nitrogen. Therefore, decreasing the nitrogen flow will increase its purity. Through a combination of membrane bundles, different levels of purity can be reached to satisfy a number of applications.

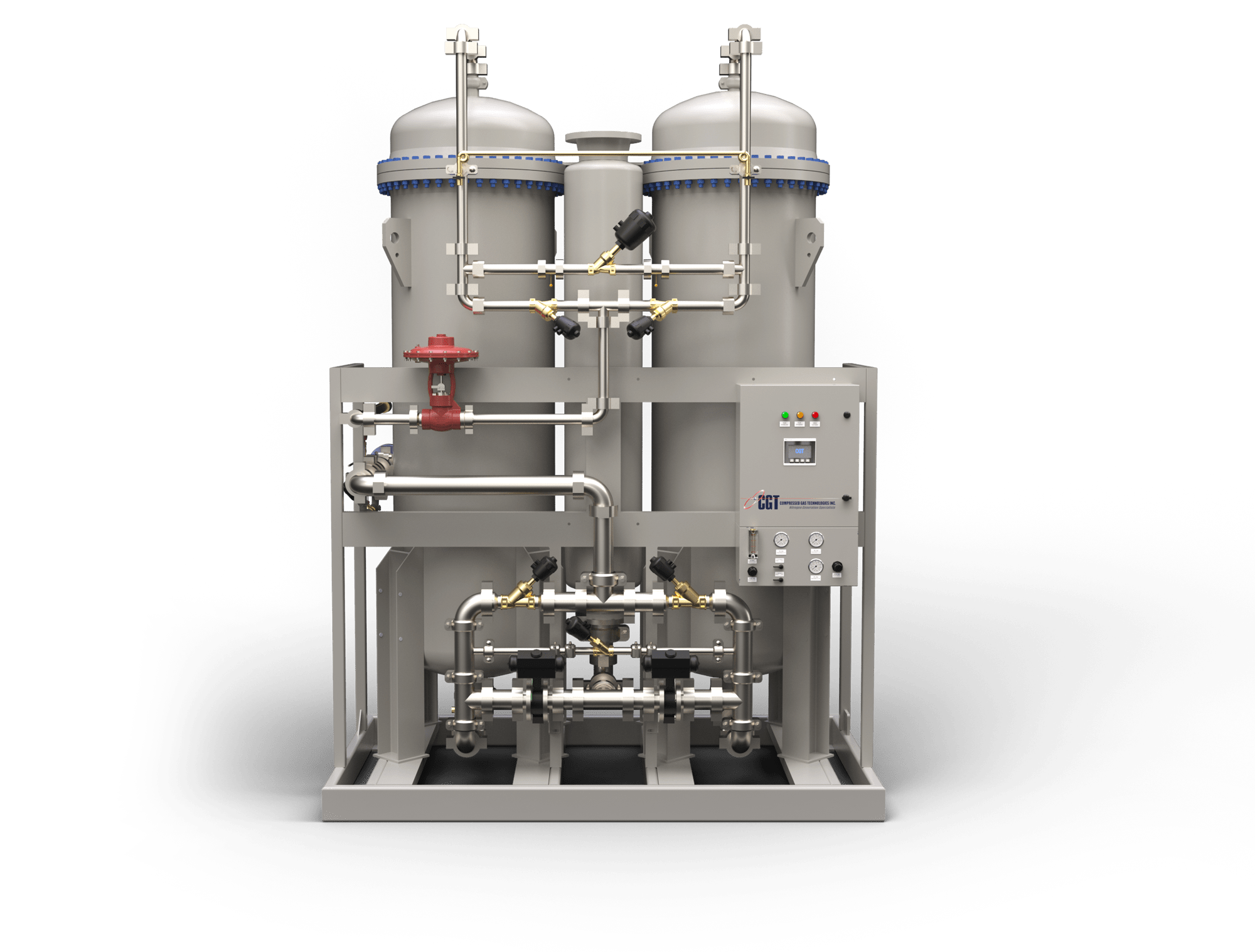

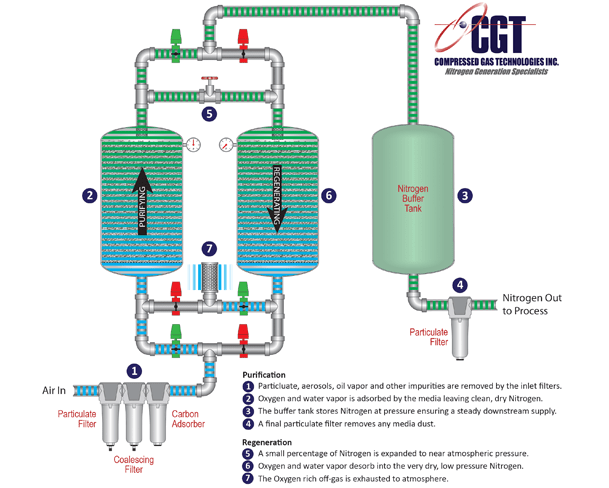

PSA Nitrogen Generators

- Air is taken through the intake valve where two chambers contain a carbon molecular sieve (CMS). The CMS contains tiny pores that are perfect for filtering out unwanted oxygen molecules and other gases. Nitrogen is able to pass through this stage undetected as its molecules are bigger than oxygen molecules.

- Over time, the CMS will have absorbed too many oxygen molecules to separate the gases effectively. For this reason, PSA nitrogen generators are always designed with at least two chambers – one for actively separating gases and the other being purged with high purity nitrogen to eliminate the build-up of oxygen. Typically, the generator will switch between the two chambers about every 60 seconds.

Compressed Gas Technologies is Your Leading Generator Manufacturer

If you want to maximize your savings potential, it’s time to get in touch with Compressed Gas Technologies Inc. Discuss your flow, purity and pressure requirements with our nitrogen generation experts who can help you design a system that works for your specific application and needs. Whether you choose a membrane or PSA model, on-site nitrogen generation technology is far more beneficial than any other nitrogen gas delivery system. Backed by almost 20 years of experience in the industry, we have been a leader in nitrogen generator installation and operation throughout North America. For more information about our products and how an on-site nitrogen generator can benefit your business, contact us today.

For all Canadian and US-based inquiries, please contact our office at +1 (877) 737-7760, by email at sales@nitrogen-generators.com or fill out our online form for more information about our nitrogen generation products and services.