Blog

Nitrogen and Beer: Part 1 – Dispense

If there is a better way to spend a warm summer afternoon than sitting on an outdoor patio, sipping a frosty cold beer, it’s probably illegal. Craft breweries around the U.S. and Canada have not missed the opportunity to capitalize on the growing trend of more sophisticated beer palates. In 2014, some 5.4 billion pints of craft beer were brewed in the U.S. alone.

The brewers behind this growth are part evil genius, part mad scientist, and part brilliant chef. These masters of the mash treat each recipe with great respect as their reputation is directly linked to every sip.

But beer can be a fickle mistress. Every aspect of production, storage and delivery will affect the final experience. A perfectly balanced stout, for example, will suffer from a poor dispense method. Ignoring how beer gets from a keg to a tap and into the glass is like running a flawless 25 miles only to lay down on the last mile of a marathon.

The issue for many beers run through long tap lines is pressure. For the majority of beers, CO2 is used as the force to push beer from keg to tap. But CO2 is very soluble (it easily goes into solution). When higher pressure is involved, like what’s needed to push beers a long distance or through a diffusing tap like with Guinness, the CO2 dissolution is even greater.

To some degree the lightly bitter flavor that CO2 adds is a boon for many brews. But for more balanced, malty beers like stouts, it can offset the smoother, creamier notes. When this is the case, nitrogen is the answer.

A mix of N2 and CO2 – typically 75/25 or 70/30 – offers a better option for motivating malty beers than straight CO2. Nitrogen does not so easily go into solution and does not add the same slightly bitter flavor. This mix also aids in pushing beers like Guinness through the diffuser that gives the beer its signature foamy head.

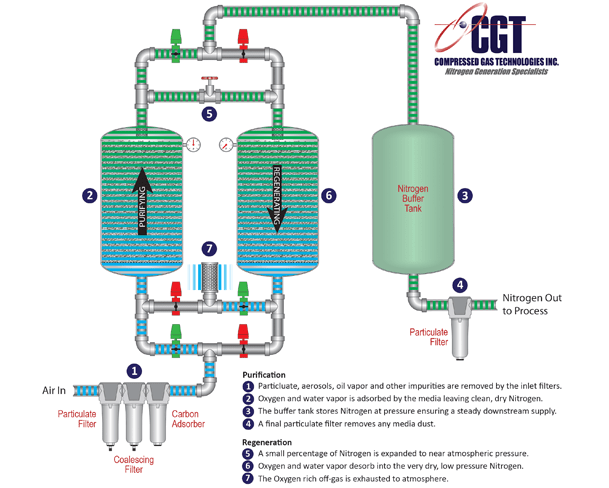

Of course, when you’re running a busy tap room, the last think you want to do is replace bottle after bottle of gas. The perfect option is a small nitrogen generator. The system takes a supply of compressed air, cleans it and strips out the oxygen. The N2 gas is then blended with a bottled supply of CO2 (there isn’t an alternative to delivered CO2), and continuously fed to the beer dispense system.

Brewers and brewpub owners are a particular bunch. And when they want something done right, they go to the experts. Compressed Gas Technologies has helped hundreds of nitrogen users disconnect from the bottle and switch to a more sustainable supply of gas. No matter the technology, membrane or PSA nitrogen generators, CGT has the range of products and experience to provide the answer.

Keeping unwanted CO2 from dissolving into malty beers is a real problem; however, CGT can provide the solution.