How PSA Nitrogen Generators Benefit the Food Industry

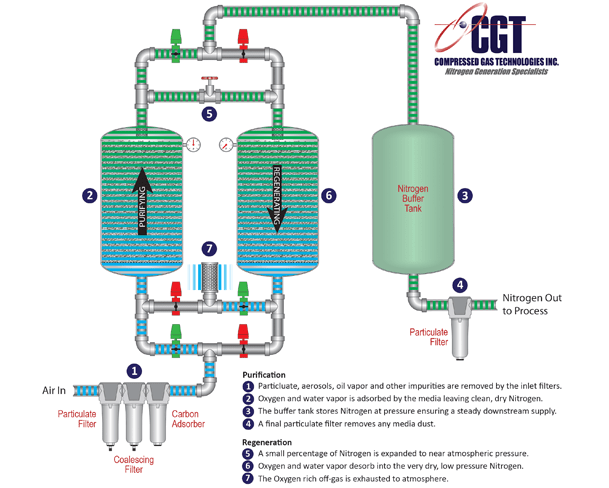

Suited for a range of different applications, compressed nitrogen gas has long been used in the food manufacturing and packaging industries to help preserve the freshness and quality of perishable products. Nitrogen purging displaces oxygen from various types of packaging such as cans, bottles, plastic and cardboard containers before they are sealed for distribution. Oxygen is responsible for introducing moisture which rapidly deteriorates food; thus, compressed nitrogen is an inexpensive and readily available, non-chemical alternative to protect nutrients and ensure the quality of various food items. If you are considering an on-site nitrogen generation system, Membrane or PSA nitrogen generators from Compressed Gas Technologies Inc are ideal for this purpose.

How is Nitrogen Used in Food Manufacturing and Packaging Industries?

Purging food packaging of oxygen with compressed nitrogen is a safe practice and has become widely regarded as the industry standard over the years. If you work in the food industry, your number one priority should be food safety. Here are all the benefits of incorporating a food-grade nitrogen generator into your business operation:

- Maintain Integrity of Products: When nitrogen is used for packaging, the gas minimizes oxidation and the flavour changing effects that typically occur if oxygen is present. When used in the packaging of raw materials such as cooking oils or seasonings, a nitrogen-infused atmosphere stabilizes the product and preserves its taste.

- Prevents Aerobic Microbial Growth: Oxygen can encourage the growth of microorganisms, especially when it comes to meats, veggies, and other ready-to-eat products. Modifying the atmosphere of your packaging with nitrogen is an extremely effective way of ensuring that it is safe for public consumption. Including higher levels of nitrogen can prevent this microbial growth.

- Increase Distribution Distances: If there is a greater presence of oxygen, it is more likely that your product will decompose at a faster rate than it would if the oxygen was replaced with nitrogen gas. Through blanketing your packaging with food-grade nitrogen, you can prolong the shelf-life of your product and gain the ability to increase your distribution times and distances.

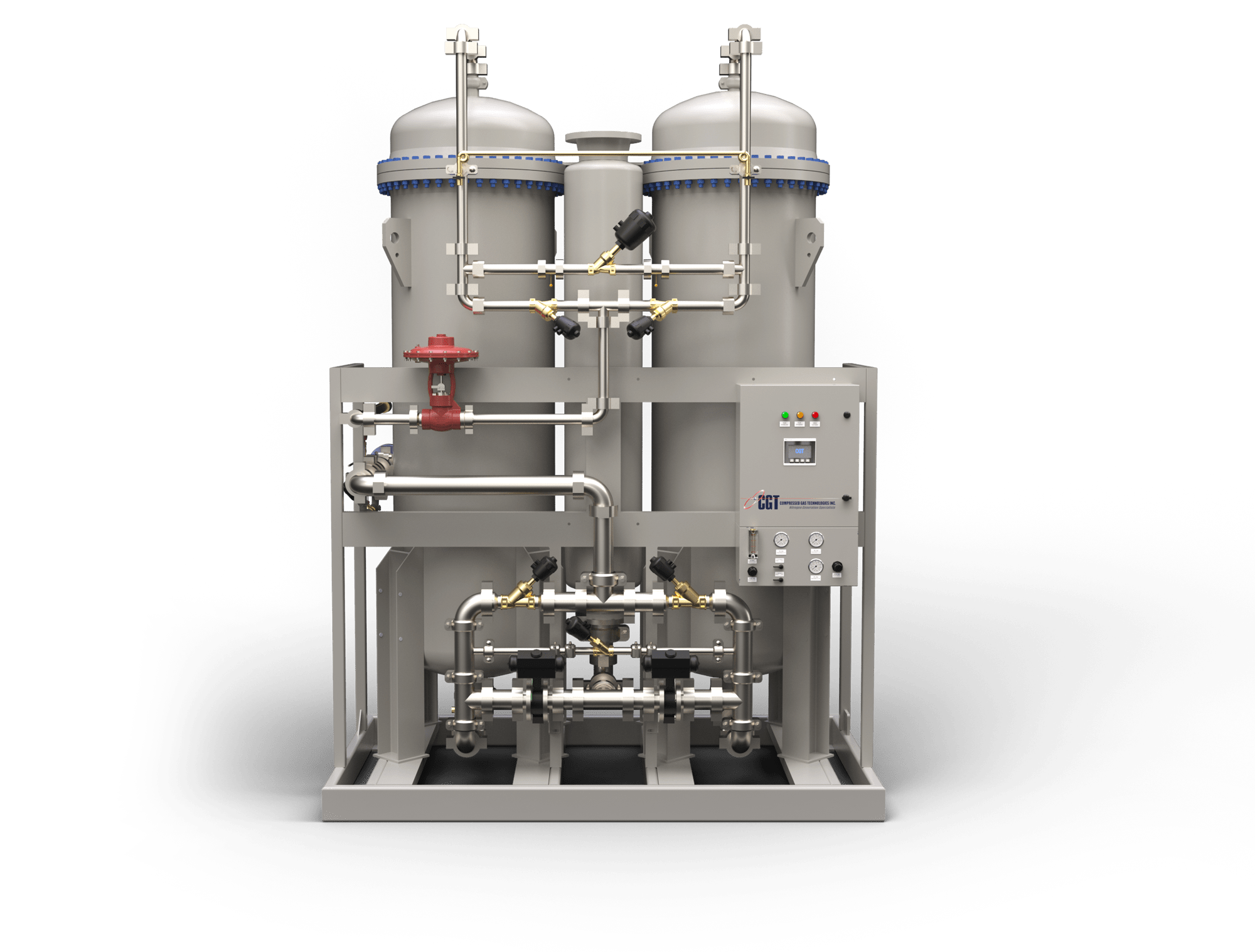

- Unlimited Supply of Nitrogen: Switching to an on-site PSA nitrogen generator will protect the quality of your products and therefore, benefit your bottom line. In addition to being the most sustainable option, a nitrogen generation system will provide you with a quick, unlimited supply of nitrogen that in turn, eliminates your need to hire or buy from a supplier.

Explore Our Range of Membrane and PSA Nitrogen Generators

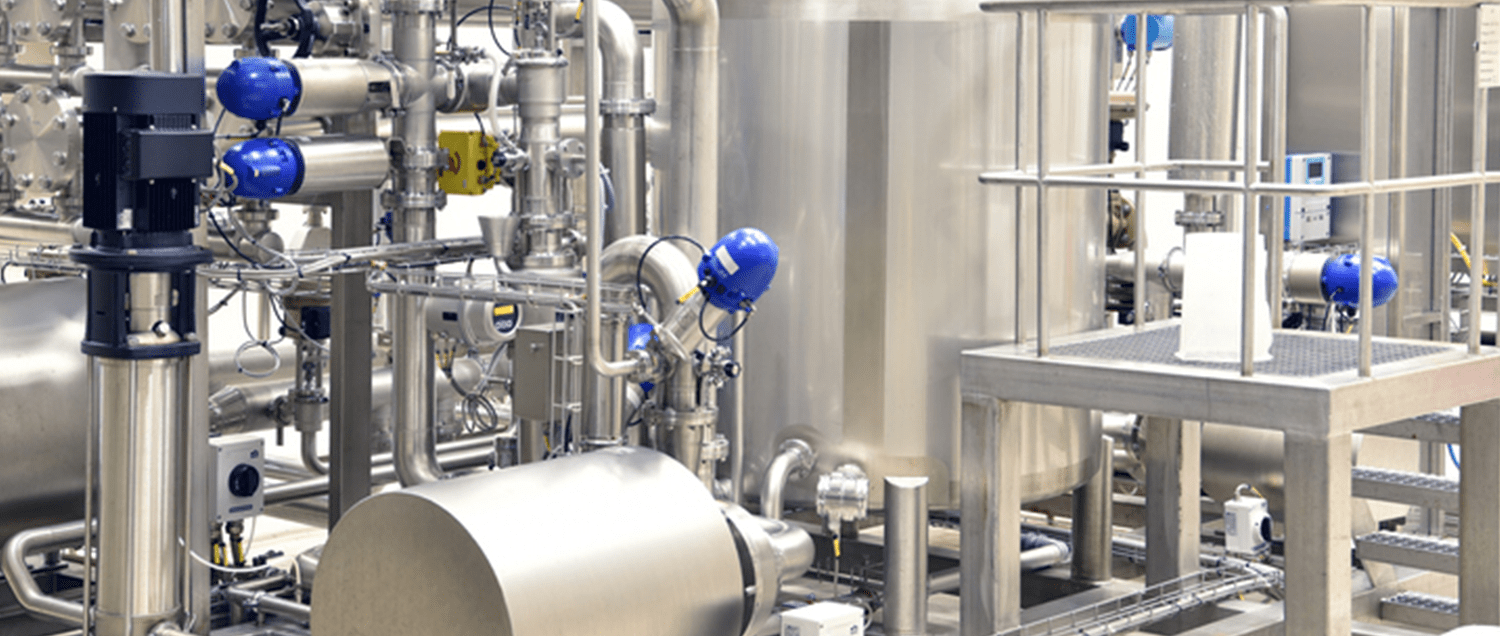

To help food get from the farm or factory to the grocery store and finally, the dinner table, manufacturers turn to a technique called Modified Atmosphere Packaging (MAP). MAP is a highly effective packaging method that measures out the optimal atmosphere a certain type of food needs to stay fresh for as long as possible. It uses nitrogen gas to reduce the oxygen content that would otherwise rapidly spoil the product. Our generators are thoroughly inspected to meet industry standards and are supplied to you as complete systems which are easy to set up, operate and maintain.

For all Canadian and US-based inquiries, please contact our office at +1 (877) 737-7760, by email at sales@nitrogen-generators.com or fill out our online form for more information about our nitrogen generation products and services.