Blog

Keeping Halloween Alive! Milk Powder Storage and Nitrogen

It’s the week after Halloween and the kids are sleeping off their sugar-buzz hangover. You’re working through the mini-math; remembering how many fun-size treats you consumed and how that calculates to full size candy bars. You are, of course, not alone.

Candy is big business and the precipice of the confectionery calendar is Halloween. More candy is sold in the weeks leading up to All Hollow’s Eve than any other time of year. In the U.S. that’s 600 million pounds – roughly five times more than Easter and Valentine’s Day combined.

Most of that candy is shelf stable so transportation and storage from production to consumption isn’t a problem. Many ingredients, however, fall prey to spoilage while in storage at the production facility. Ruined ingredients cost money and add complexity to the production and purchasing processes.

Milk Powder Storage and Nitrogen

Extending the shelf life of items such as peanut butter and milk powder by storing in a nitrogen atmosphere not only reduces waste but allows for a more consistent quality in the end product.

In 2009 the American Dairy association published a study which evaluated the effects of temperature and nitrogen flushing on the storage of whole milk powder. The powder was tested at three month intervals by a panel of experts for changes in flavor and by chemical analysis for lipid oxidation volatiles (LPOs). The researchers concluded that flushing with nitrogen, not storage temperature, reduced the presence of LPO’s and had a greater positive effect on maintaining flavor (Lloyd, Hess, Drake, 2009).

One potential obstacle to flushing storage containers with nitrogen is cost. There are three ways to have nitrogen delivered by the gas company: high pressure cylinders, portable liquid dewars, and stationary liquid bulk tanks

High pressure gaseous cylinders are the delivery method of choice when only a small amount of nitrogen is required. Each holds about 300 cubic feet of gas. A typical storage flushing application can use this much gas in less than an hour which means managing thousands of gas cylinders each year – not a practical solution.

Facilities with only one or two storage areas may be able to use a portable liquid nitrogen dewar. These stainless steel vessels contain enough liquid N2 that, when boiled off into gas, provides approximately 3000 cubic feet of nitrogen. The user is charged per dewar with an average cost of 75 cents to $2.00 per each 100 cubic feet of gas delivered.

Most food producers will opt for a stationary bulk tank. The customer typically leases the tank and accepts delivery of liquid N2 which is expanded into gas on site. At an average cost of 35 to 60 cents per 100 cubic foot this is the most cost effective delivery option. It is not uncommon, however, for the total bill to be in the 10’s and 100’s of thousands of dollars each year.

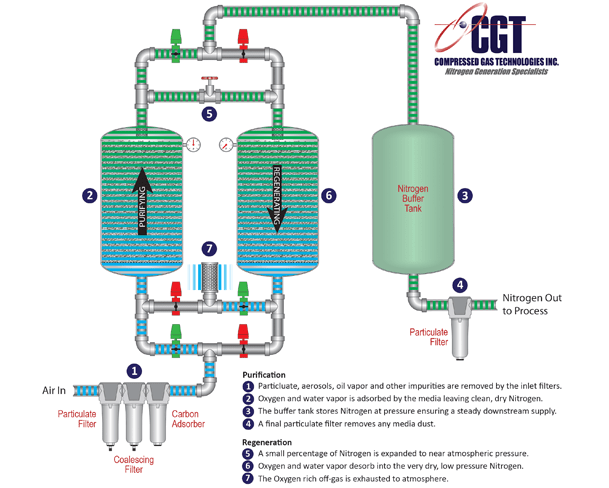

Using your compressed air source to produce nitrogen on site can be the most cost effective option of all. The average cost for nitrogen using this method ranges between 10 and 25 cents per 100 cubic feet. If nitrogen is used four or five shifts per week this cost savings will usually pay back the capitol price of the generator in a year or two.

A qualified professional such as Compressed Gas Technologies can produce a return on investment calculation for your facility. The report will show how quickly you break even on the capital expense of a nitrogen generator and when you can begin to reduce your N2 bill by 50 to 90 percent. Some pretty sweet savings for any confectioner.