Tag Archives: nitrogen generation

Small Nitrogen Generators: When Compact Systems Make the Biggest Impact

Are you struggling to fit nitrogen generation into a small facility?

Wondering if a compact system can really deliver the performance you need?

Fortunately, te...

The ROI of Switching to On-Site Nitrogen Generation

The Big Question: Is On-Site Nitrogen Worth the Investment?

If your business relies on nitrogen for production, packaging, or processing, you’ve probably wondered—i...

How Nitrogen Gas Benefits the Food Packaging Industry

In the following we will aim to help explain how on-site nitrogen gas benefits the food packaging industry in preserving freshness, food quality, and integrity throu...

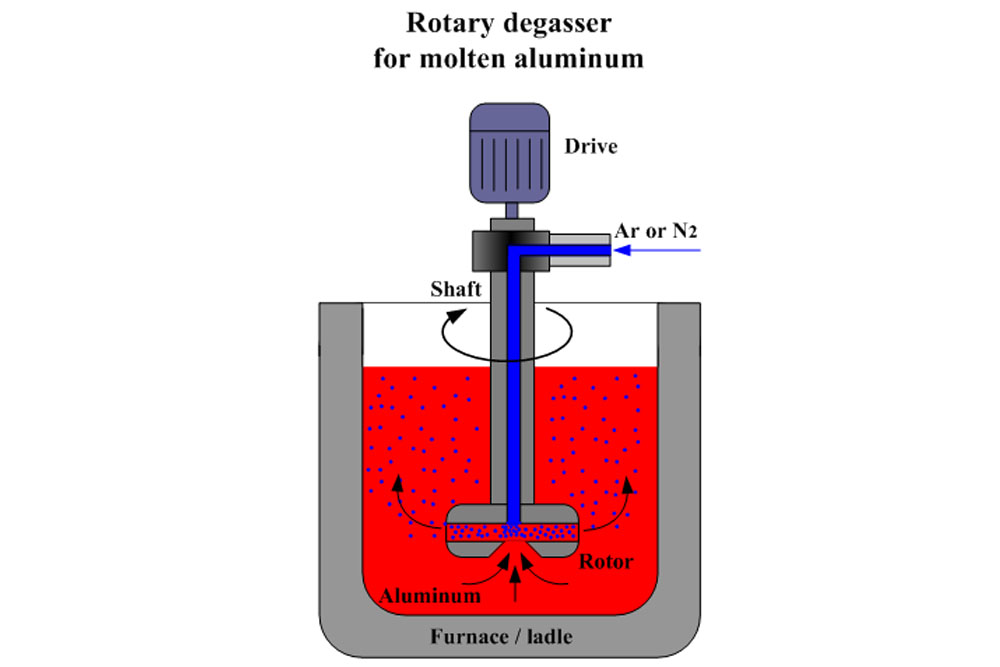

What are the industrial uses of nitrogen gas?

Nitrogen is an inert gas; suitable for a wide range of industrial applications. It covers numerous aspects of manufacturing chemicals, processing, handling, and ship...

How to Choose the Right Nitrogen Generator for Your Business

Nitrogen generation systems are used in several industries around the world, from aerospace and engineering to food packaging and more. After all, for companies that...

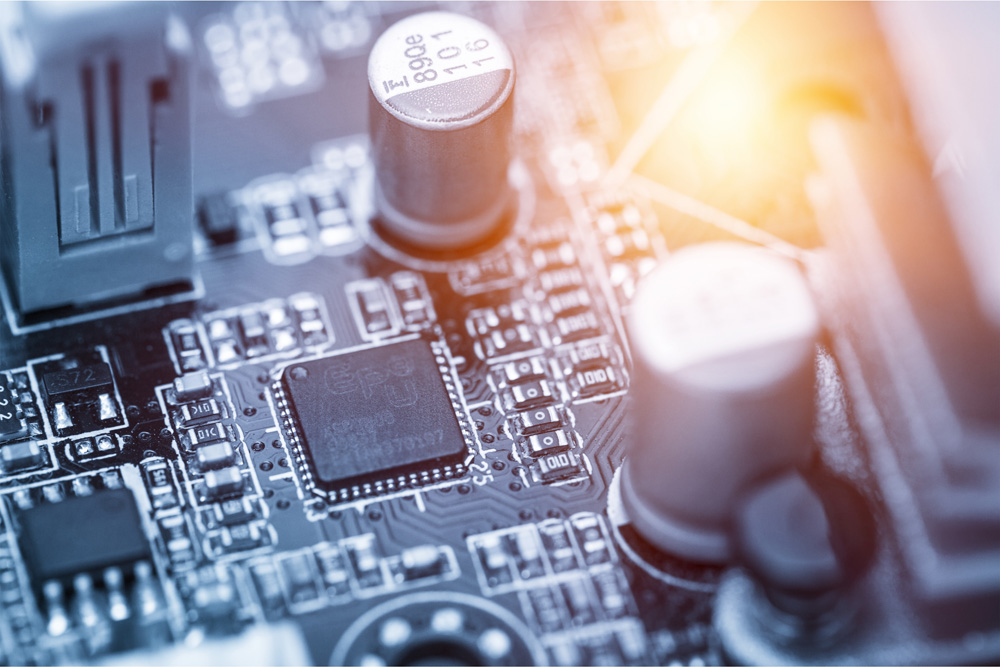

The Benefits of Using On-Site Nitrogen Generators in the Electronics Industry

In recent years, nitrogen gas has been frequently used in the field of electronics manufacturing. The industry is extremely complex and demands accuracy and precisio...

Using Nitrogen Generation for Coffee Industry Applications

For many of us, coffee is a staple for all those early mornings. This classic hot beverage is not only delicious, but it can also help fuel the day ahead. In order t...

How Nitrogen Generators are Used in a Laboratory Environment

In a laboratory environment, nitrogen gas is mainly used to control a highly sensitive atmosphere. Ideal atmospheric conditions are essential for maintaining a safe,...

How Nitrogen Generators Assist in Precision Laser Cutting

Laser cutting is a process where metals like stainless steel and aluminum are cut for industrial and commercial uses with a high-powered, precision laser beam. Typic...

How Does an On-Site Nitrogen Generator Work?

Generating your own nitrogen rather than outsourcing it has three main advantages including lowering costs, eliminating wait time and delivering consistent purity. C...

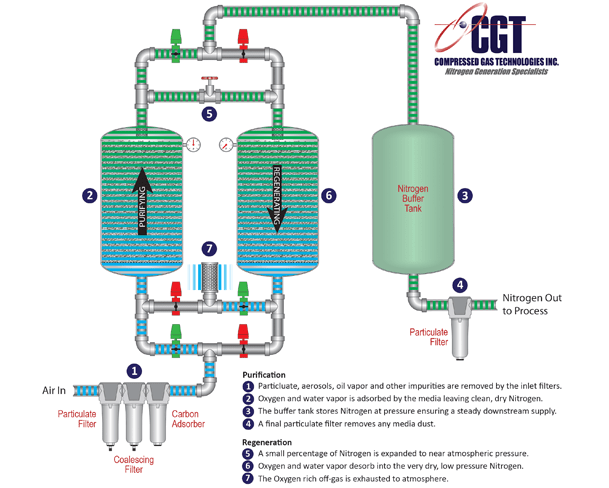

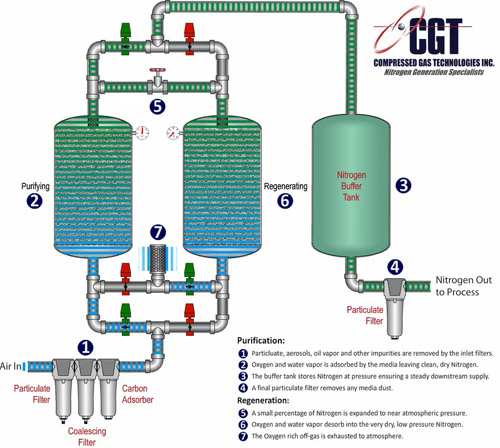

What is a Pressure Swing Adsorption (PSA) Generator?

Nitrogen makes up a large component of the air we breathe. Thanks to on-site nitrogen generation, you can take advantage of this unlimited nitrogen source and save y...

The Role of Industrial Nitrogen Generators in Modified Atmospheric Packaging

If you work in the food and beverage industry, then you already know how time sensitive your packaging process can be. From the moment your product leaves the produc...

Why More Breweries and Wineries are Choosing On-Site Industrial Nitrogen Generators for their Business

Compressed nitrogen gas is used for a number of different industrial applications around the world. The use of nitrogen has become especially popular in the brewing ...

The Benefits of Nitrogen Generators for Laser Cutting

Lasers are used for a number of purposes in the metal processing industry. Generally, manufacturers use lasers to cut metals like steel, aluminum and other raw mater...

CGT Turns 18!

Since starting out in November 2001, Compressed Gas Technologies has established itself as an industry leader throughout the United States and Canada. Over the las...

Energy Companies – PSA and Membrane Nitrogen Genertors

CGT regularly works with various energy companies located in Houston for various projects. Recently we have supplied nitrogen generators to their facilities in Alask...

Nitrogen Generator for Appliance Manufacturer

One of the world’s largest appliance manufacturers required a small flow nitrogen generator for their lab. The lab manager had used Compressed Gas Technologies befor...

Nitrogenated Sodas

Love soda but don’t like the carbonation? Nitrogenated sodas are now hitting the market. Pepsi announced earlier this year they would be launching Nitro Pepsi. It wo...

Waste Disposal Company Installs PSA Nitrogen Generator

A leading waste disposal company located in Cincinnati, Ohio recently installed a PSA nitrogen generator. The new high flow, low purity unit will replace a smaller m...

Major gas supplier announces second price increase in 3 months!

Air Products recently announced they will be increasing pricing for bulk liquid nitrogen effective January 1st, 2019. This is the second increase in the last 3 month...

Portable Customized Nitrogen System for US Defense Contractor

CGT was contacted by a large US defense contractor to help them with a portable customized nitrogen system that would allow them the ability to move the nitrogen gen...

Nitrogen Generator for Pizza Packaging Line

One of the largest pizza chains in the United States recently installed a CGT high purity nitrogen generator to supply food-grade nitrogen for their new packaging li...

PSA Nitrogen Generator for Polymer Manufacturer

CGT installed a high purity modular PSA nitrogen generator for a leading polymer manufacturer located in Georgia. The nitrogen generation system is operating around ...

Automotive Fuel Systems Company Installs Modular Nitrogen Generator

A manufacturer of automotive fuel systems contacted CGT looking to reduce their nitrogen costs. Their sister company had installed a CGT nitrogen generator the year ...

Spring Maintenance for your Nitrogen Generation System

Spring is a good time to check your nitrogen generation system to ensure it will be ready for the upcoming hot summer months. The feed air compressor should have the...

On-Site Nitrogen Production

How On-Site Nitrogen Works

The air we breathe is roughly 78% nitrogen and 21% oxygen. By simply taking atmospheric air and compressing it to >100 psig, we can th...

Is Your Nitrogen Generator Operating At Maximum Performance?

Just call us; we are here to help!

Without regular maintenance, NITROGEN GENERATORS don’t perform their best and can become very costly if they require major repair...

Are you ready to join in on the savings?

Since 2001, Compressed Gas Technologies Inc. has been setting the reliability standard by supplying high quality nitrogen systems with units that have been in operat...

What size nitrogen generator do I need?

Sizing a nitrogen generator is typically very straight forward and our technical sales team will be able to walk you through the process. Call CGT now and talk with ...

Stop wasting time – ask an expert!

CGT sales staff are experts in nitrogen generation, that is all we do. Instead of spending countless hours researching nitrogen generation, a quick 5-10 minute phone...